Change Language :

Gluing robot

An adhesive robot automatically applies adhesives, sealants, paints and insulating foams. The advantages are obvious:

- More precise application of the adhesive

- Less material wastage

- Fast and reliable feed-through

- Exact repetitions

- Consistent quality

The areas of application for bonding robots are very diverse and independent of the industry. Thanks to the modular principle of the igus® robotic components, you can implement almost any gluing process and adapt it flexibly as required. We would be happy to advise you on which type of robot is best suited to your bonding and sealing process.

Configure your bonding robot in 5 simple steps:

Adhesive application in the automotive industry

At the Volkswagen plant in Emden, a robolink® articulated arm robot is used in Passat B8 PA production.

Two adhesive seams are applied by the gluing robot for gluing acoustic measures in the area of the rear battery console in order to avoid tedious manual labour by employees and to increase the quality of the gluing process.

- Automated feeding of the part to be glued

- Constant application of the adhesive mass

- Reduction of manual, error-prone processes

- cost-effective bonding processes through the use of Low Cost Automationsolutions

Adhesive application in machine production

Wolfsburg-based tapofix GmbH uses a room linear robot from igus® for the precise application of sealant.

The faster and perfectly dosed application of the sealant by the robot has eliminated tedious and time-consuming manual labour. The result is higher production capacities and consistently high processing quality:

- Precise dosing of the adhesive quantity

- Precise and constant distribution of the adhesive mass

- Consistent production quality

- Cost-effective integration and rapid amortisation

Adhesive application in lamp production

The LOCTITE universal spray dispensing system and an igus® room linear robot enable precise adhesive application. High repeatability can be achieved thanks to the high web fidelity of the gantry and the optimised pressure of the dispenser.

- Reliable bonding of different materials

- Flexible filling quantities

- Consistent adhesive pattern and precise dosing

- Cost-effective bonding processes through the use of Low Cost Automationsolutions

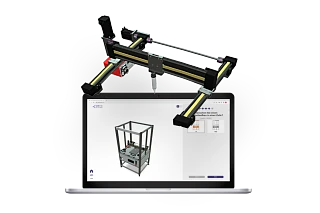

To the gluing solution in five clicks

Configure automation solution online

- Save individual design effort

- Compatibility of all installed components guaranteed

- Minimal use of resources thanks to standardised systems

- Put together a robot application with 5 clicks and receive an immediate quotation

Low Cost Automation Support

Do you need help with product selection or your project? You can reach us via these channels:

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr