Change Language :

Current news

Never miss any more news from igus. Register now for our free e-mail newsletter:

igus GmbH becomes igus SE & Co. KG

November 21, 2025 | The conversion to an SE & Co. KG opens up new opportunities for us to successfully distribute roles: The management will take over the operational business, while Frank Blase, as Chairman of the Board, will continue to help shape the strategic direction of the company. Together, we will work on innovations and services that create real customer value and promote sustainable growth.

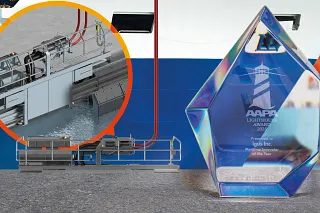

Recognition for sustainable port solution: igus wins “Maritime Innovator of the Year” award

November 19, 2025 | With its Mobile Shore Power Outlet (iMSPO), igus has developed a mobile shore power system for ports that can be moved flexibly depending on the position of the ships at the berth. The system allows ships to shut down their diesel engines in ports, switch to more environmentally friendly shore power and thus significantly reduce their CO2 emissions. For its central role in promoting sustainable and flexible port operations, igus has now been honoured as “Maritime Innovator of the Year”. The award was presented during the conference of the American Association of Port Authorities (AAPA) in Quebec, Canada.

New PTFE-free 3D printing resin from igus with up to 122 times better wear rate

november 17, 2025 | Many manufacturers of laboratory technology, diagnostic devices and surgical robots produce plastic components using 3D printers, such as miniature gears, rotating valves or swivelling levers. This helps you save time and money. The problem: many printing materials contain so-called PFAS chemicals. The EU might restrict these in future due to a potential risk to people and the environment. “Many manufacturers in sensitive industries such as medical technology are therefore already looking for alternative materials for 3D printing,” says Jonas Burk, Head of Additive Manufacturing at igus. “One such alternative is our new iglidur i2000, a 3D printing material that does not contain any of the 96 PFAS substances considered critical in concentrations above 0.1% by weight.”

More safety in cleanrooms with new polymer ball bearings from igus

November 11, 2025 | In addition to energy chains, igus now also offers ball bearings made of abrasion-resistant high-performance plastics for cleanrooms. The new polymer bearings in the xiros series already fulfil the highest requirements of cleanroom production. They have been specifically developed for highly sensitive applications in battery production and the semiconductor industry, for example for use in conveyor rollers. The new ball bearings are characterised by very high resistance to abrasion and chemicals as well as minimised particle emissions.

igus wins DLG Innovation Award for ReBeL cobot

November 11, 2025 | Plastic specialist igus receives the prestigious Systems & Components Trophy – Engineers’ Choice Award from the German Agricultural Society (DLG). The ReBeL cobot – a compact, cost-efficient robot arm that sets new standards for automation in agriculture – won the award. In future, the robot will fulfil protection class IP67 so as to function reliably even under challenging environmental conditions.

ReBeLMove Pro: modular robot platform for logistics, assembly and handling

November 2, 2025 | Pressure in terms of costs and efficiency demands a lot from modern production. With the ReBeLMove Pro, igus is launching a modular autonomous mobile robot (AMR) that is easy to customise according to the modular principle – from small load carrier transport to robot solutions. It can be integrated into company processes without any previous experience. The ReBeLMove Pro is available from just €39,800, which makes it around 25 per cent more cost-effective than most competitor models.

Cable guide without a chain: igus develops new low-profile system for safe cable movements

October 30, 2025 | With the new pull-e-cable design study, igus is presenting a particularly low-profile and cost-efficient solution for guiding cables over long travels – without the need for a classic energy chain. The system is ideal for applications with limited installation space and a low budget, for example in camera technology, laboratories, moveable displays or automation.

4-year guarantee on reliable performance: new chainflex cables for stage technology

October 23, 2025 | Cables in theatre and stage technology have to work hard. Stage spaces are often narrow and complex, and cables have to withstand tight bend radii and frequent movements over long periods of time. A technical failure can quickly lead to a premature end of the evening. To ensure that the cables are both fail-safe and unobtrusive, igus has now developed a new and unobtrusive series of its highly flexible chainflex cables. igus will present the new industry solution and other new products at the SPS in Nuremberg.

Technology without compromise: igus presents new PTFE-free and PFAS-tested products at plastics trade show K

October 8, 2025 | PFAS and PTFE (a subgroup of PFAS) have been present in many products worldwide for decades – whether pans, shoes or hoses. It is due to them that plain bearings, e.g., can operate in dry operation without lubrication. However, the organic fluorine compounds decompose very slowly and can be harmful to people and nature. The discussion about a possible ban is causing uncertainty in the industry. As a pioneer for lubrication-free high-performance plastics for motion, igus recognised this challenge at an early stage and has already developed its own PTFE-free materials. At the K plastics trade show in Düsseldorf from 8th to 15th October, the company will show that this change is not only possible, but can also be linked to technical improvements. October (Hall 5, Stand D05).

igus invests in the future of its skilled employees with a new Training Factory in Cologne

October 8, 2025 | Many companies complain about a shortage of skilled labour. igus, however, is taking on responsibility and increasingly training junior staff. A new Training Factory at the company headquarters in Cologne-Porz will support this project, doubling the training capacity for professions such as mechatronics/electronics technicians and tool mechanics. The company intends to be independent from external specialists as early as 2027. In addition to the Training Factory, the company is also increasingly focussing on adult education in cooperation with the Chamber of Industry and Commerce (Industrie- und Handelskammer, IHK).

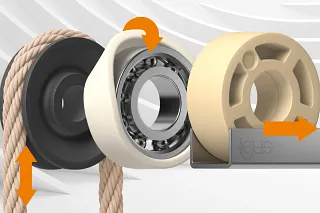

Now in series production: igus presents new durable skate wheels, pulleys and roller adapters

October 7, 2025 | Three at one fell swoop: due to high demand, igus is launching new pulleys, skate wheels and roller adapters in series production, which were previously only available as customised products. Manufactured from high-performance plastics, the new components are an economical alternative to classic metal counterparts in numerous applications. They are lubrication-free and insensitive to dirt, durable, maintenance-free, vibration-dampening and ensure a quiet operation.

Attention design engineers! igus launches application phase for the 10th vector award

October 7, 2025 | The starting signal for the application phase of the vector award 2026 has been given. For the tenth time, a joint initiative is honouring designers worldwide who use energy chains made of high-performance plastic to create cable guides that set new technological standards. The winners receive up to 5,000 euros in prize money.

Family business with a future: igus in the finals of EY Entrepreneur Of The Year 2025

September 29, 2025 | In Germany, there are a lot of family businesses with strong development despite the challenging times. igus is one of them. The Cologne-based company started out in 1964 with plastic components such as industrial plain bearings and energy chains. It is also constantly tapping into new and promising business areas, e.g. low-cost robotics. This agility is one of the reasons why igus is a finalist in the globally renowned competition “EY Entrepreneur Of The Year 2025”. According to the organiser Ernst & Young, this makes igus one of the best owner-managed companies in Germany that are shaping the future with confidence.

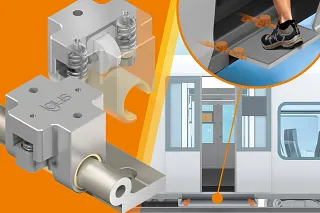

2-in-1 world first: drylin W hybrid roller bearing combines smooth operation and heavy duty

September 23, 2025 | Many design engineers are familiar with the problem: they want a particularly smooth-running guide for pull-out mechanisms that can withstand high loads without wearing out quickly. Examples are retractable steps in train carriages, plinth solutions in the furniture industry or laboratory equipment. Classic lubricated metal ball bearings are out of the question as they require too much maintenance and are not sufficiently weather-resistant. It is precisely for this application that igus has developed the new hybrid roller bearing with roller retraction system for the drylin W series. Thanks to its crafty design, it combines smooth operation with heavy duty.

65 times more wear-resistant: igus develops ball bearings for extreme chemical loads

September 19, 2025 | igus has developed two new chemical-resistant and particularly durable xiros ball bearings especially for use in contact with chemicals. They are 65 times more wear-resistant than ball bearings made entirely of the plastic polyether ether ketone (PEEK). This durability is due to a combination of races and balls made of technical ceramics and a PEEK-based igus cage. Designers in the chemical and process industries, aerospace and the automotive sector, among others, benefit from their long service life.

Winning the RoboCup world championship with igus in 2025

September 15, 2025 | Design engineers can considerably increase the efficiency of autonomous logistics robots with linear modules from igus. The RoboCup World Championship in Brazil in 2025 will prove this as robots from all over the world will handle products in a simulated factory. Here, the Carologistics team from Aachen has succeeded in implementing a fast, precise and reliable gripper system using igus linear axes from the drylin ZLW series. With this solution, the team won the world championship title and set a new world record.

Dash across the water without corrosion

September 12, 2025 | Rushing across the water on a motorised surfboard: the Jetsurf combines the thrill of jet-skiing with the feel of a motorbike. The engineers at Czech manufacturer MSR Engines rely on igus plain bearings made of high-performance plastic to ensure that the fun in salt water is not spoilt by technical failure. The polymer bearings make the sports equipment more efficient in many respects.

Space saving made easy: igus launches compact slewing ring bearing

September 10, 2025 | With a new compact version of its PRT-04 slewing ring bearing, igus offers a space-saving solution for precise rotary movements under medium loads. Due to lubrication-free high-performance plastics in the sliding elements, the bearing is maintenance-free and corrosion-resistant – ideal for modern machines with limited installation space.

Made from one piece: the energy chain E1 for particularly compact installation spaces

September 9, 2025 | Whether in food-vending machines, laboratory equipment or electric doors: whenever space is at a premium, designers often dispense with guides for individual moving cables – and thus risk cable damage and unnecessary maintenance costs. A new, one-piece, injection-moulded and particularly compact energy chain made of high-performance plastic from igus is designed to put things right. As this product is currently still a design study, the Cologne-based motion plastics specialist is now looking for interested companies that would like to use the energy supply systems in pilot projects and develop them further to series production.

Through the toughest solar rally in the world with igus

September 5, 2025 | Driving through the desert with solar power! The Sonnenwagen team from RWTH Aachen University and Aachen University of Applied Sciences demonstrates its viability. Students have built a solar car with lightweight and robust components made of lubrication-free high-performance plastics from igus and have thus taken on the ultimate challenge: the Bridgestone World Solar Challenge 2025, the toughest solar rally in the world. The team fought its way to fourth place on the 3,000-kilometre route across Australia. A triumph for German engineering and sustainable mobility.

Rethinking city traffic: new e-vehicle relies on maintenance-free polymer bearings from igus

August 30, 2025 | Owning a car is becoming less and less important for many young people in cities. Studies show that the proportion of pedestrians and bicycles is increasing significantly, especially in urban areas. The car as a status symbol is losing its appeal – instead, the focus is shifting to sustainable, flexible and low-maintenance mobility solutions. JetBike GmbH from Braunschweig is embracing this change and presenting a pioneering solution with the JetBike: an innovative combination of e-bike and car. To fulfil the requirements regarding sustainability and ease of maintenance, the company relies on lubrication-free polymer bearings from igus.

Uninterrupted power supply at lorry ramps: safer logistics thanks to e-spool flex

August 20, 2025 | A faulty power connection on a lorry ramp can bring the entire logistics process to a standstill. Cable reels with slip rings are a common weak point. With the e-spool flex, igus is launching a new type of solution that does not require slip rings (which are susceptible to faults) and allows for a reliable power supply – even under harsh conditions.

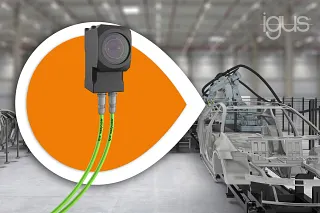

igus expands readycable portfolio with new cables for industrial camera technology

August 12, 2025 | igus is expanding its range of harnessed readycable for moving industrial applications. New additions to the portfolio are cables with plug connections for systems from Keyence, one of the world’s leading manufacturers of automation and quality assurance solutions. Designers can immediately connect the ready-to-connect cables to moving high-speed cameras using the plug-and-play principle, for example, and thus make them even more fail-safe – without time-consuming and error-prone in-house designs.

Fighting the weeds with ease

August 5, 2025 | The AX-1 robot from Norwegian start-up Kilter applies herbicides to weeds with such precision that the use of chemicals is reduced by up to 95% – thanks to AI and sensor technology. To ensure that the autonomous helper is also gentle on the soil, the developers rely on lightweight and lubrication-free linear technology from the igus drylin series.

Metaprint automates the loading of printing machines with XXL linear robot from igus

July 16, 2025 | Customised automation doesn’t have to be expensive. Metaprint AS from Estonia, one of the largest manufacturers of aerosol packaging in Europe, demonstrates this. The company now uses an XXL linear robot from igus to load a printing machine. Compared to conventional systems, this Low Cost Automation solution reduces investment costs and is also easy to put into operation thanks to the plug & program function.

Saving 88% of lorry transport volume with new rack for energy chain systems

July 16, 2025 | The efficient use of loading space is becoming increasingly important in view of the growing volume of lorry traffic on German roads. igus has therefore developed the new readychain eco-rack. The transport and assembly rack for pre-fitted energy chains consists of strong multiplex panels made of birch wood. In contrast to classic metal racks, it can be dismantled without tools. During return transport, it saves up to 88% of the original transport volume, reducing CO₂ consumption and transport costs. The eco-rack is now available for customers of the readychain service.

Get customised components faster and easier with the igus tribo-parts service

July 10, 2025 | 3D printing, CNC production or injection moulding? When design engineers are looking for the most suitable manufacturing process for a customised component, they often lose track of things, which costs valuable time. The igus tribo-parts service changes this: a free online tool that enables design engineers to find the most efficient manufacturing process in terms of cost, delivery time and service life for the required component – with just a few clicks and on one page.

elko celebrates new cable harnessing with customers, suppliers and employees

July 8, 2025 | elko Verbindungstechnik opens its doors following the acquisition by igus and the modernisation of the factories. With new technologies and ultra-modern processes, elko presents itself in a new light. Together, customers, suppliers and employees celebrate the lean production line and future opportunities. The expansion of harnessing capacities in the field of drive technology and the proximity to customers in southern Germany are intended to help elko and igus respond even more flexibly and quickly to the customer needs.

World first: ESD-certified dress pack for maximum safety in electronics production

July 1, 2025 | igus launches triflex TRE ESD, the world’s first ready-to-connect dress pack for industrial robots that is now ESD-certified, including all connection elements. The solution tested by Fraunhofer IPA significantly reduces design effort and increases safety in sensitive production areas such as microelectronics, the semiconductor industry or in the component production of battery systems. The system can be seen for the first time at automatica 2025 in Munich.

1,500 applications used in production: igus brings Low Cost Automation to its own factory – and to automatica

June 30, 2025 | Fewer tedious tasks, faster processes and greater efficiency: plastics specialist igus relies on extensive automation in its own production and logistics. Over 1,500 applications such as cobots, autonomous vehicles and delta robots are already in use, and the number is growing every day. The message: automation doesn’t have to be expensive or complicated.

Playful robotics training: igus Low Cost Automation proves its worth in everyday school life

June 18, 2025 | Getting young people excited about technology: this is the aim the plastics specialist and robotics manufacturer igus pursues with its educational programmes specifically for schools, colleges and universities. This also includes the ReBeL education kit: a learning package designed to give pupils and students a playful introduction to robotics with the help of the ReBeL cobot. The education kits are used at the Georg Simon Ohm vocational college in Cologne, among others. This gives students the opportunity to acquire their first programming skills and try out practical applications.

High-precision and durable gear from 3D printing with up to five times longer service life

June 17, 2025 | Three years ago, plastics specialist igus launched its first resin, iglidur i3000. It is characterised by its high resolution and precision in the DLP process for producing wear-resistant parts. “Over the last two years, we have noticed an increasing demand for lubrication-free gears in a wide variety of shapes and sizes. Resins are a very good option as the process allows for component quality similar to that of injection moulding,” explains Jonas Burk, Head of Business Unit Additive Manufacturing at igus. This is why igus has pushed ahead with its research into synthetic resins and developed iglidur i4000, a material that is particularly suitable for manufacturing wear-resistant and precise gears.

igus launches compact electric telescopic extension

June 13, 2025 | From service robotics to medical technology to vehicle equipment: consumers are getting used to automated motion systems. To realise them in confined installation spaces, igus has developed the new, low-maintenance and electric telescopic extension drylin NTM-45.

Reduce assembly work by 80% with separable igus polymer flange bearings

June 12, 2025 | If a conveyor belt in the woodworking industry breaks down due to a defective flange mounted bearing, every second costs money. To reduce assembly work by up to 80% in such an emergency, igus presented new flange mounted bearings from the igubal series at the LIGNA 2025 trade show in Hanover. The bearings made of robust high-performance plastic are divided into two parts and can be replaced without dismantling the shaft.

A second chance for animals and used electronics

June 12, 2025 | With their own trainee company “reguse”, the trainees and students of the Cologne-based company igus ensure that old electronic devices from igus employees find a second life within an environmentally friendly circular economy. They donate part of their annual turnover to charitable organisations. This year, €5,000 will go to the animal welfare organisation Notpfote Animal Rescue from Neuss.

Plastic on the move: the igus:bike continues its tour – this time through Europe

May 27, 2025 | After the start in Germany and successful stops in Asia, the igus:bike world tour is now continuing its journey in Europe. The launch in Spain marks the start of a new stage in the global mission: to raise awareness of a functioning circular economy for plastics. The aim of this world tour, which will also include the USA and Brazil after Europe, is to drive 6,000km without any lubricants, maintenance or rust.

igus expands D1 motor control with certified PROFINET

May 22, 2025 | igus increases the flexibility of its D1 motor control, which designers use for electric linear drives, handling systems and robot axes. It is now possible to integrate the D1 seamlessly and quickly into higher-level control systems from Siemens, Beckhoff, Wago and other manufacturers using Siemens-certified PROFINET – without time-consuming and complicated adaptations. This extended connectivity should significantly increase the performance and efficiency of automation processes.

For less than €50,000*: igus presents humanoid robot Iggy Rob

May 7, 2025 | Humanoid robots are on the verge of revolutionising the industry. While previous systems are very expensive, motion plastics specialist igus is now offering its first humanoid robot, Iggy Rob, as a low-cost solution. For €47,999, it supports companies in industrial production, service or with transport tasks. To gain experience with the new helper, igus is calling on companies to “test before they invest”.

igus launches wear-resistant plain bearing range without PTFE

April 30, 2025 | Just in time for Hannover Messe, igus is announcing a breakthrough: the material developers in Cologne have succeeded in producing the established polymer plain bearings from the iglidur G, iglidur X and iglidur H series, which are used in machines, systems and vehicles worldwide, without PTFE. This is good news for a lot of companies that are already looking for future-proof alternatives due to the prospect of stricter PFAS regulations or even a ban.

Safety in battery production due to long-term tests: new dry-cleanroom certificates for igus e-chains

April 23, 2025 | Two years ago, igus presented the E6.29, the first certified energy chain for dry cleanrooms. In order to offer customers long-term security, the motion plastics specialist commissioned the Fraunhofer IPA to carry out a test to investigate the ageing behaviour of its e-chains in the dry cleanroom – with positive results. Together with the IPA, the company has now developed new certificates that confirm the suitability of the energy chains E6, e-skin flat, e-skin soft and easy chain E14 for dry cleanrooms in long-term tests.

80% lower CO2 footprint: igus switches to recycled material for energy chain series E2.1

April 16, 2025 | Following the successful development of the world’s first energy chain made from recycled plastic, motion plastics specialist igus is taking the next step: the company is converting the entire catalogue range of its standard energy chain series E2.1 to the new recycled material igumid CG LW.

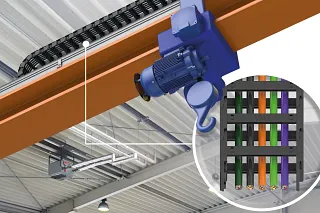

Reduce costs for indoor cranes by up to 40% with new igus glide-chain

March 27, 2025 | The energy chain specialist igus is presenting its new energy chain called “glide-chain” at the Hannover Messe. It has been developed specifically for gliding applications and is ideal for travels of up to 30m, as is the case with indoor cranes, for example. Its slim design ensures cost savings of 30 to 40%.

Surgical microscope for structurally weak countries wins manus plastic bearing competition 2025

March 27, 2025 | A mobile surgical microscope from Prechtl Tech Solutions for structurally weak countries has won the manus plastic bearing competition 2025. A jury of experts recognised the engineers who used lubrication-free polymer bearings and were thus able to increase the reliability of the microscope. Other winners of the competition include a bicycle trailer for parcel delivery, an AI hoe for agriculture and an agrivoltaics system with irrigation and cultivation system. They have all created ecological, economic and social benefits by switching to lubrication-free plain bearings made from high-performance plastics.

igus reaches one-billion mark in sales and increases the number of active customers by 5%

March 25, 2025 | With 277 motion plastics innovations in 2025, igus is presenting a record number of new lubrication-free plastic products in line with the motto “GO ZERO Lubrication”: from PTFE-free materials and a complete energy chain series made of recycled materials to a new type of dry cleanroom certificate and a humanoid robot. This is the result of continuous investment in research and development to offer customers state-of-the-art solutions. Despite the challenging geopolitical and economic situation in 2024, the motion plastics specialist was able to increase the number of active customers by 5% and maintain its billion-euro turnover. With sales of €1.105 billion, the company recorded a comparatively moderate decline in turnover of 2.5%.

Now it’s clicked: PTFE-free positional system from igus for precise adjustment

March 20, 2025 | Whether moving to specified spots with a sensor, adjusting a headrest to the desired height or getting a screen into an ergonomic position until it clicks: igus has launched the new linear guide with PTFE-free drylin WWP locking carriages for simple positioning tasks, e.g. in the interior. The solution is intuitive, compact, durable and, thanks to the material combination of lubrication-free high-performance plastics and aluminium, particularly light, hygienic and low-maintenance.

This robot piggybacks 600kg shelves

March 11, 2025 | The French company SCALLOG has developed an autonomous robot called “Boby” that can transport shelves weighing up to 600kg in logistics warehouses. To maximise the robot’s range and minimise maintenance, the engineers rely on lubrication-free iglidur plain bearings from plastics specialist igus, which are wear-resistant and significantly lighter than comparable metal solutions.

Game-changer for ports of the future: igus equips the 2,000th STS crane with e-chains

March 5, 2025 | Seaports are under pressure worldwide: to remain competitive, terminals have to handle larger ships in shorter periods of time. Therefore, more and more operators use modern components such as igus’s robust energy chains that are compatible with Industry 4.0. The motion plastics specialist has now equipped the 2,000th STS crane with e-chains and is making more and more terminals fit for the future.

Record participation in the igus plastic bearing competition manus

March 3, 2025 | This record participation in the manus award 2025 from igus impressively demonstrates the innovative power and creativity of engineers around the world. The competition recognises the creative use of plastic bearings in machines, systems and vehicles, with a focus on the economic, ecological and social benefits. With 613 registrations from 38 countries, the competition noted an increase of almost 28% compared to 2023.

Close to the customer, delivered quickly: igus takes over harnessing specialist elko

February 4, 2025 | igus announces the acquisition of elko Verbindungstechnik GmbH. With this step, the company is expanding its assembly capacities in the field of drive technology. At the same time, the motion plastics specialist from Cologne is now even closer to its customers in southern Germany, the centre of the German machine tool and automotive industry.

RBTX Academy: takeaway robot knowledge training from igus

January 30, 2025 | Robots are being used in more and more areas, from production in factories to care for the elderly. To help companies of all sizes realise the full potential of automation solutions and thus become more competitive, igus is now opening the RBTX Academy. Here, interested parties can work directly on real robots to learn the basics of robot technology or improve their skills in robot programming. The RBTX Academy opened its doors for the first time on 25th January, when igus hosted the dress rehearsal for RoboCup Junior 2025 – one of the best-known and largest robotics competitions for pupils in the world – at the Porz-Lind site in Cologne.

Get a cost-effective robotics system even faster: new AI robot advisor for RBTX.com is online

January 9, 2025 | igus has added a new AI chatbot to the online platform RBTX.com. The interactive consultant is designed to enable companies with little previous experience and technological expertise to quickly and reliably put together Low Cost Automation (LCA) solutions to become more competitive. First users are enthusiastic about the intuitive AI solution.

motion plastic news

Stay up to date on igus and our products. Our free newsletter offers you new products, exciting applications, current laboratory reports and much more.