Change Language :

igus bearing technology

No lubrication, no maintenance

What do our iglidur ® plain bearings, xiros ball bearings, igubal ® spherical plain bearings and iglidur ® PRT slewing ring bearings have in common?

Compared to pure metal bearings, they are up to 80% lighter, vibration-damping, maintenance-free and self-lubricating. This not only saves time and money, but also protects the environment.

A study by RWTH Aachen University is the first to show the enormous savings potential of self-lubricating plastic bearings in terms of lubricant, labour and maintenance costs.

Discover our product range and benefit from the unique specifications of our bearing products!

Our bearing technology with high-performance polymers

igubal®

Self-adjusting, low-wear and dirt-resistant spherical plain bearings

Spherical bearings

xiros

Corrosion-resistant, low-noise and optionally non-magnetic ball bearings

ball bearings

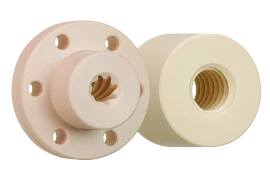

iglidur®

Bearings in various types, materials and in more than 10,000 sizes

Plain bearings

iglidur® PRT

Robust, lightweight and cost-effective slewing ring bearings for precise rotary movements

PRT slewing ring bearings

dryspin®

Lubrication- and maintenance-free lead screw technology in various sizes, pitches and types

lead screw technology

drylin®

Linear rails for various applications and industries

DOES THAT HAVE TO BE THE CASE?

Annual maintenance of 13 hours prevents the labelling of 650,000 bottles

Krones, a leading global manufacturer of packaging systems, trade show was faced with the challenge of being able to label up to 650,000 fewer bottles per year due to 13 hours of annual maintenance work. The implementation of igus®' maintenance-free sliding and linear technology solved this problem. This led to a significant reduction in maintenance and lubricant costs, enabled the production of an additional 650,000 bottles and improved the smoothness of the bearing, which had a positive impact on the operators. In addition, the new solution allows regular annual maintenance without additional interruptions.

Success stories: lubrication-free bearings save time and money

Many well-known companies have already been able to save time and money by using our lubrication-free bearings. Krones AG, for example, saves over €50 and 13 hours of maintenance time per year by using one plastic plain bearing per labelling station. Heineken Brasil uses self-lubricating igus® bearing technology in conveyor belts, thereby increasing reliability and minimising downtime. Rockinger uses a self-lubricating wear insert in the KS80 ball coupling, which eliminates the need for lubrication and reduces maintenance work to a minimum, and Lemken, which specialises in the manufacture of agricultural machinery for soil cultivation, sowing and crop protection, saves 22 lubrication points per cultivator.

Heineken Brasil

Savings with 600 storage locations:

2,815.49 € Costs¹

1,560 h maintenance²

180.08 kg CO2 equivalent³

Rockinger

Savings per trailer coupling:

87.36 € costs¹

13 h maintenance²

1.4 kg CO2 equivalent³

Lemken

Savings per cultivator:

88 € Costs¹

14.7 h maintenance²

6.3 kg CO2 equivalent³

1Annualcost savings through the use of plastic plain bearings per machine/system

2Annualtime savings through the use of plastic plain bearings per machine/system

3Annualsaving of CO2 equivalents through the use of plastic plain bearings per machine/system

Why do our bearings work without lubrication?

The savings potential of igubal spherical insert bearings

| Cost savings with 200 pieces | ||

|---|---|---|

| Spherical ball | igubal JEM | |

| Costs for 200 pieces | €1,350 | €300 |

| Estimated service life | 1 year | 4 years |

| Costs for lubricants (per year) | €45 | €0 |

| Hourly time required for lubrication (every year): 3 min. per bearing x 24 times every year x 200 bearings | 240hrs | 0hrs |

| Hourly rate per employee (€30/hr) x lubrication (240hrs) | €7,200 | €0 |

| Total annual costs | €8,595 | €75 |

| Annual savings | €8,520 |

white paper

The advantages of the lubrication-free bearing arrangement of our plain, ball and PRT slewing ring bearings