Change Language :

Two in One: Tandem-toothed belt axis

Thanks to the double belt, the ZLWT tandem-toothed belt axis is ideal when several linear slides need to be moved quickly and independently of each other. The motors can be mounted on one or both sides. A parallel synchronised drive is also possible.

- Addition to the tandem-toothed belt axis installation size 10/20

- Compact tandem-toothed belt axis with two toothed belts in one unit

- Two slides can be controlled synchronously or separately

- With drylin® W-exchange bearing for quick bearing replacement on the rail

- Available ready for connection with igus® electric motors and D1 motor control unit

Typical areas of application: Automation, robotics, assembly cells, painting systems

Product services

Advantages of the Two in One toothed belt axis

Tech up

- Toothed belt axis with double toothed belt based on the drylin® W linear guide system

- Synchronised operation or separate control of two linear carriages

- Prepared for the connection of two NEMA stepper motors/DC motors

- Suitable as a seventh axis in robotics for moving two robots

Cost down

- Uses one linear axis instead of two

- Wide design ensures full strength

- Reduced design cost and effort thanks to linear axis/motor/motor control system delivery from a single source

- All pillow blocks can be replaced directly on the rail without dismantling

- Cost-effective replacement kit consisting of pillow blocks, lids, and assembly tools

Proof

- drylin® W service life can be calculated online

- Subjected to a long-term test in the igus laboratory

- Bearing replacement on the rail in less than 30 seconds

- Motor control system can be simulated online

Sustainability

- Two carriages positioned with just one axis

- Clean and lubrication- and maintenance-free

- Pillow block can be replaced, all metal linear axis components can be re-used throughout the service life

Manual or automated format adjustment

When do I use what?

Testing the tandem-toothed belt axis in the laboratory

The robust design with lubrication-free drylin® W linear plain bearings ensures a long service life and maintenance-free operation. This was confirmed in the igus®-test laboratory.

ZLWT - tested and proven: 400,000 cycles without maintenance

- Motor: igus® EC DC motor and gearbox

- load: 1.500N

- stroke: 1,500mm

- Speed: 0.3m/s

- Customer specification: 400,000 cycles

- End of test: 412,654 cycles

- Target achieved: YES

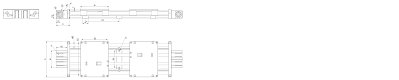

Technical drawing

More information

Consulting

I look forward to answering your questions

Michael Hornung+49 2203 9649 0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr