Change Language :

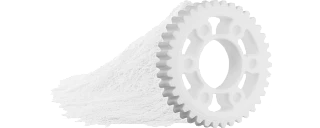

3D printed plastic gears for charging system for electric cars

Time and cost savings with the igus® 3D printing service

Configured quickly online

An online design for gear at the igus® 3D printing service takes around 60 seconds. Delivery then takes 24 hours. This is different to gear wheels, which are produced using industrial printers and are ready for dispatch in up to 3 days. "High flexibility and fast delivery times are crucial when building prototypes," says Easelink founder Hermann Stockinger. "It is precisely this specification that we appreciate about the possibility of quickly selecting and printing a wide range of variants from igus® gear using the online configurator."

Another advantage, in addition to the unbeatable time savings, is the cost-effectiveness of the igus® service, as all tool costs are eliminated. The designer only has to select the tooth module and specify the number of teeth and the torque transmission. The configurator creates a 3D model of the gear, the basis for 3D printing. Hundreds of variants of simple gears and double gears can be realised without the need for computer-aided design (CAD) software.

iglidur® i6 for high wear resistance

The iglidur® i6 is particularly suitable as a printing material for gears. The high-performance plastic defies ambient temperatures from -40 to +80 degrees Celsius, is pressure-resistant up to 44 MPa and has a high abrasion resistance. Laboratory tests have proven that it is significantly more robust than the classic plastic polyoxymetylene (POM). In these tests, gears were run at 12 revolutions per minute and loaded with 5 Nm. The result: the 3D-printed gear made of iglidur® i6 was still fully functional even after one million cycles, with hardly any measurable wear. A milled gear made of POM was different. It was worn out after 321,000 cycles and broken after 621,000.

Buy SLS material iglidur® i6 online

Consulting

I look forward to answering your questions

Dirk Tietz+49 2203 9649 562Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr