Change Language :

Storage technology for temperatures up to 300 degrees in the fully automatic pizza oven from BistroBox

Toothed belt axles, cable routing, gear wheels and other bearing technology in a maintenance-free pizza oven.

A freshly baked pizza in just 90 seconds at the touch of a button? The BistroBox is a self-service pizzeria with Austria's first fully automatic pizza oven. The centrepiece of the innovative combination of refrigerated storage system and pizza oven is lubrication- and maintenance-free storage technology such as a conveyor belt axis and other storage technology that ensures the pizza is transported from the cooling station to the oven and finally to the customer. All components must fulfil the high hygienic requirements of food technology ... at temperatures of up to 300 °C.

Products used

drylin® drive technology

energy supply

3D printing material

Slewing ring bearing

igubal® Spherical plain bearing

tribotape® Sliding films

xiros ball bearings

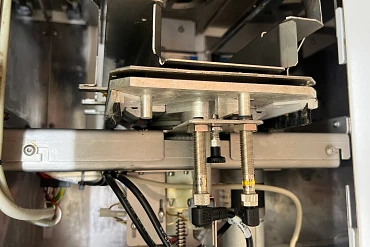

Figure 3: The platform with the pizza, which moves along the toothed belt axis, can be pulled out. 3D-printed gear and gear racks help here.

Image 4: In this station, the pizza is freed from its packaging. The platform in the station rotates around its own axis several times. This is made possible by a PRT slewing ring bearing.

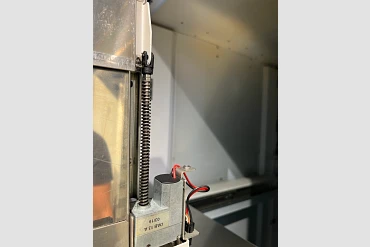

Figure 5: igubal® clevis joint with spring hinge pins work in the closing mechanism of the oven door.

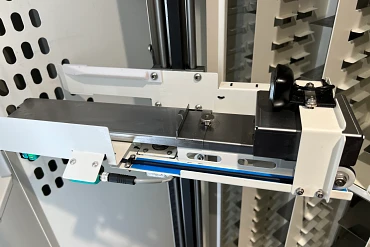

Figure 6: The FDA-compliant blue tribotape® sliding film reduces wear at friction points within the vending machine.

Figure 7: Low-friction bearings: xiros ball bearings in the vending machine.

More information

Consulting

I look forward to answering your questions

Andrej Schmidt+49 2203 9649 9850Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr