Change Language :

Now for robots, too - intelligent 3D energy chain condition monitoring

i.Sense TR.B: Avoid unplanned downtimes and high downtime costs now, even for multi-axis and industrial robots, with smart plastic's smart condition monitoring for triflex® R energy chain.

The functionality of i.Sense TR.B is shown again in the video here:

Die hohen Dynamiken und Belastungsgrenzen der triflex Energieketten lassen sich am besten im Video demonstrieren.

i.Sense EC.P - intelligent push/pull force monitoring successfully implemented

When do I need a smart condition monitoring system like i.Sense EC.P?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

i.Sense in daily use on linear chains

- The i.Sense EC.B (EC = e-chain, B = breakage detection) sensor is installed at the moving end of the e-chain (in the video it still has the smaller sensor box for short travels)

- Special mounting brackets also allow the EC.B sensor to be installed on the moving end of the e-chain

- A cable is stretched through the e-chain, which picks up all changes in length and reports them to the new EC.B rope hoist sensor.

- This detects chain breakages, switches off the system and prevents consequential damage

10 tips for energy supply on the robot

Download free white paper

This guide shows you step by step how to select, install and commission an energy supply system for axis 3-6 on an industrial robot. The first points are about positioning the cable and hose pack and selecting the right energy chain.

Then you choose the appropriate retraction system. Helpful tips on assembly and a final checklist round off the ten-point package and provide step-by-step instructions for both amateurs and professionals.

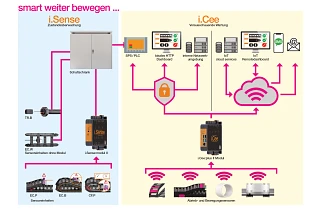

Integration into your own network environment

As part of the i.Sense condition monitoring system from smart plastics, all data from the new EC.B sensor can also be analysed in the i.Cee control cabinet module. This can then be used to digitally control the entire alarm and escalation management of the system.

The i.Cee module can also be integrated into predictive-maintenance concepts in a number of ways. From preventive service management, which schedules regular maintenance depending on use, to location-independent fault management, which immediately reports any unforeseen change via various mobile channels. All information is collated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Overview of smart plastics

Insight into the complete igus product portfolio for Industry 4.0

Contents of this free brochure:

- Condition Monitoring (i.Sense)

- Systems for condition monitoring

- Advantages of condition monitoring systems

- Application examples of condition monitoring

- Predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive-maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr