Change Language :

Order turned parts and milled parts online

Our CNC service enables stress-free procurement

of your turned and milled plastic parts.

Benefit from these advantages:

► Transparent instant costing ✔️

► Automated feasibility and tolerance checks ✔️

► Components ready to ship from three days ✔️

► Predictable service life ✔️

Our CNC service is complemented by what igus® is all about: our many years of experience as your material supplier, manufacturing partner and application consultant. Together with you, we will find the perfect solution for your application. We offer you over 30 different iglidur® high-performance plastics, so that your turned and milled parts can be optimally designed for almost any requirement.

You can find this on the page

Tolerance check

Check your technical drawing automatically using our tolerance check:

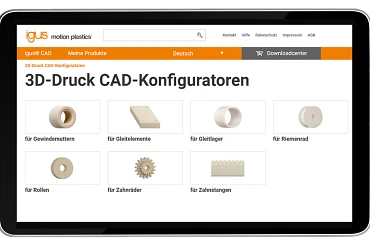

3D model configurator

No 3D model at hand? No problem, try our 3D model configurator.

6 reasons for turned and milled parts made of plastic

The right material for your project!

We offer you more than 50 tribologically optimised materials for innumerable applications in which wear-resistance is a necessity. Irrespective of whether your application is exposed to high temperatures, contact with media or wear-intensive conditions – igus® almost always offers a solution.

"We wanted to make efficient use of a short maintenance interval to replace existing PA bearing with customised bearings from iglidur®. The very fast quotation calculation and express shipment of the igus® online CNC service enabled us to procure the CNC parts in just a few days and get the production line back into operation on time"

Tom Oldach, Project Engineer at Dr. Quendt GmbH & Co KG

Click here for the complete user story

Refer to our manufacturing standards

This guarantees plastic-compatible production and rapid machining of your turned and milled parts.

✓ The general tolerance ISO 2768-m/K applies for plastic-compatible tolerancingwith regard to length, shape and position

✓ Deviating from this, the following minimum tolerance widths according to DIN ISO 286 are normally possible:

(Caution: The minimum tolerances that can actually be realised always depend on the specific component geometry, the material selected and the production options available, and may be greater in individual cases)

- Nominal dimension up to 30mm: IT 9/10

- Nominal dimension over 30 to 180mm: IT 10/11

- Nominal dimension over 180 to 500mm: IT 11/12/13

- Nominal dimension over 500mm: Statement only after individual testing

✓ Holes can be configured as metric ISO thread (M) (other thread types are also possible after testing)

✓ A centre roughness value Ra of 2-3 µm is to be expected for the surface quality (corresponds to the typical values of finished surfaces in turning or milling)

These standards are to your advantage: We can calculate the prices automatically and your order can be processed more quickly. You save valuable time.

Our CNC Design Guide

Our free white paper helps you with the key principles for designing your machined components.We give you 12 helpful tips for your machined parts - so you can achieve a design that is optimised for economy and production.

If you have different requirements

Requirements above and beyond our manufacturing standards are possible, provided that a prior feasibility check confirms this.After the individual check, the automatically calculated price will be adjusted if necessary.

Configure your wishes and receive direct price feedback.

When and why CNC machining is worthwhile for your turned and milled parts

Large variety of materials and material quality:

The large material variety of our iglidur® bar stock guarantees you optimum tribological component properties for every application.

High surface quality:

Due to the process, CNC machining produces good surfaces - iglidur® components normally do not require any special post-processing for their sliding surfaces either.

Precise component dimensions with tight tolerances:

You receive dimensionally accurate components with tight tolerances and fits. Narrow tolerance widths (up to tolerance grade 9 in accordance with DIN ISO 286) are usually feasible. Tolerance widths of 0.05mm are therefore no problem.

Economical for small to medium quantities:

CNC machining is often the most economical process for two to four-digit quantities, especially for large-volume parts with simple geometries.

See these application examples for yourself:

Your questions and our answers (FAQ)

What does CNC mean?

The abbreviation "CNC" (Computer Numerical Control) refers to turning or milling machines whose movements are computer-controlled in order to produce more complex shapes automatically.

What is special about our CNC service for turned and milled parts? It is simple, fast and transparent: you no longer have to wait days for the price, but receive it immediately. If you change the material or tolerances, for example, you will immediately see the impact on the price. And you can also make a purchase decision immediately. The user interface of our CNC service allows you to request quotations or send orders directly at any time. And if you get stuck, our experts will be happy to advise you.

Who can order special CNC parts from igus? Our customers include both corporate customers and private individuals.

Are there any costs involved in using the online CNC service? No, using our CNC service is completely free of charge for you. After uploading your components, all you have to do is enter your e-mail address and you can use the tool immediately. At the end, you can request a non-binding quote (button: "Request quote") and then decide whether you like it and would like to order. Alternatively, you can also order directly online (button: "Order directly").

Why doesn't igus® offer the online CNC service for other conventional plastics or metals? Our CNC service is primarily aimed at "motion plastics", i.e. plastic parts in motion. In this first step, we therefore only offer our iglidur® tribological materials, which are characterised by freedom from lubrication, wear resistance and low friction.

Bar stock online shop

In our online shop you will find a large selection of different bar stock materials.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr