Change Language :

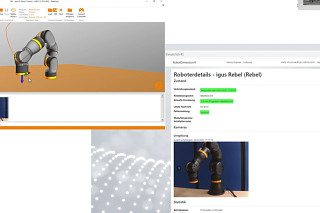

The igus Robot Control software

Program, simulate and control robots free of charge

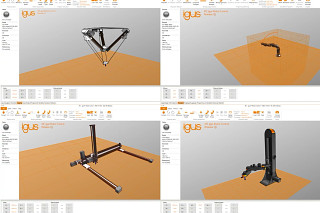

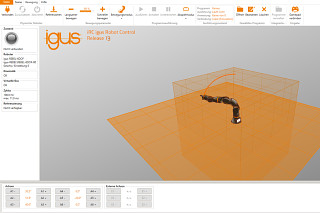

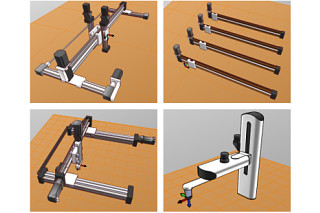

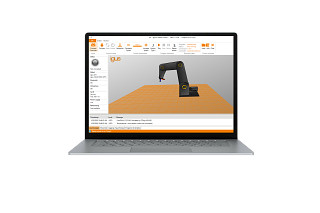

The igus® Robot Control enables simple and intuitive robot programming and control systems, making it easy to get started with automation. Thanks to the modular structure, various robot kinematics, for example delta robots, linear robots and multi-axis robots can be controlled. The software can be used to simulate the individual movements of the robot on the 3D surface - the robot does not need to be connected for this step.

Getting started in automation with the intuitive robot software as freeware

- Simple connection between robot and control system

- Intuitive operation with 3D interface and digital twin enables direct execution and checking of motion sequences

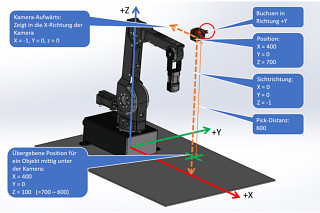

- Camera interface configuration possible directly via control system and software

- Programming of delta, linear, SCARA and articulated arm robots

- Free software enables risk-free testing

System requirements:

- PC with Windows 10 operating system

- Communication via Ethernet or WLAN

- 500MB free storage space

Interfaces

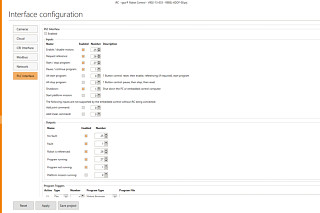

PLC interface

The PLC interface (PLC = Programmable Logic Controller) enables the execution of basic functions and the signalling of states by means of digital inputs and outputs. In addition to the control system via a PLC, this interface also enables operation via hardware buttons.

Digital inputs & outputs

Digital inputs or global signals can be used to load and start robot programs and send gripper commands. This is useful, for example, if a program is to be selected from a predefined selection using buttons or the CRI-GSig instruction.

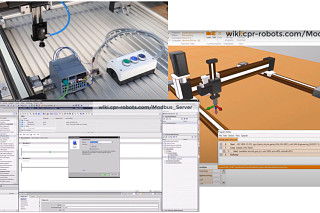

Modbus TCP/IP

Via the Modbus TCP interface, PLCs, for example, can send data and instructions to the robot control system and receive status information.

CRI interface

The CRI interface enables complex instructions to be sent and information and settings to be retrieved via the Ethernet interface using TCP/IP. iRC uses this interface to connect to robots with an integrated control system or other instances of iRC.

Camera interface

The camera interface enables the use of object recognition and video cameras. Object recognition cameras recognise the position and class of objects and transmit these, optionally with a video image, to the control system. The control system calculates positions in the robot coordinate system from the object positions of the camera. Pure video cameras only provide images and can therefore only be used to monitor the work area, but not for object recognition.

Cloud

The cloud interface enables the robot to be monitored via RobotDimension. Once activated and logged in, the robot sends basic status information and camera images to the online service. The user can list their robots on the website and retrieve the information.

ROS, Matlab, LabView, and much more.

Integrate the robots into your ROS environment. Documentation and packages for hardware communication, Teleop and moveI

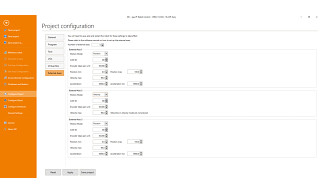

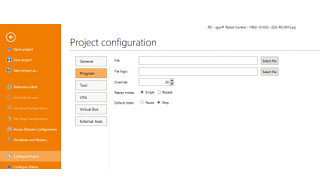

Project configurations

Gripper

The assembled tool can be specified here. Changing the tool requires the project to be reloaded or the integrated control system to be restarted. New tools can be defined as a configuration file in the directory "Data/Tools"

Virtual box

The range of movement of the robot arm is restricted by the settings of the virtual box. This functionality helps to prevent mechanical damage and simplifies programming, depending on the application. If a program is executed that violates the virtual box, it is stopped with an error message.

External axis

The robot control system supports up to three additional axes (also called "external axis" in iRC). These can be installed according to the robot axes and configured via the configuration area of iRC.

Program

Here you can define the robot and logic program, the movement speed (as per cent of the maximum speed), the playback mode and the reaction to program errors.

Special kinematics

The robot control system can be customised for your robot with a digital twin. We configure the inverse kinematics to suit your project business.

Programming

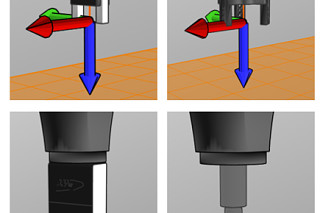

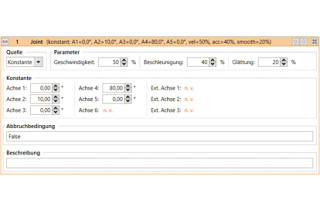

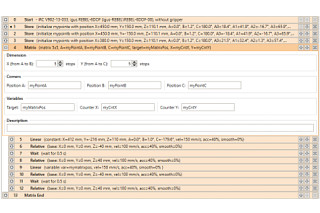

Axis movements

The command Joint moves the robot to an absolute target position that is specified in axis coordinates (e.g. axis angle or position of a linear axis). The resulting movement of the TCP is usually a curve and not a straight line.

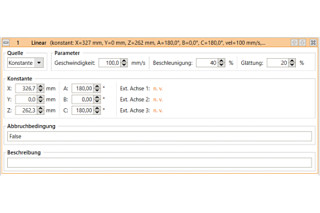

Linear movement

The command Linear moves the robot to an absolute target position specified in Cartesian coordinates. The resulting movement of the TCP follows a straight line.

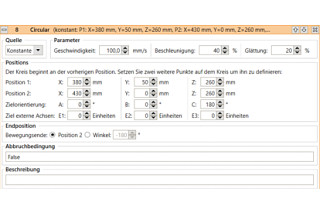

Circular movements

The instruction "Circular movement" enables movements along a full or partial circular path. It is compatible with linear movements so that the transition from and to linear movements can be smoothed over.

Conditions

Conditions can be used in if-then-else commands, loops and as cancellation conditions in motion commands. The conditions can be combinations of digital inputs, global signals, Boolean operations and comparisons.

Matrix calculation

The grid instructions calculate positions aligned to a grid, e.g. as a picking or depositing position for palletising tasks.

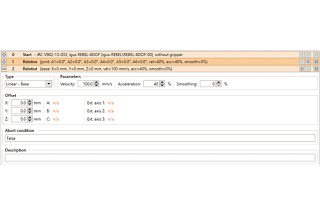

Relative

The command Relative allows you to move the robot relative to its current position. It can be accessed via the menu items at "Action" → "Relative movement".

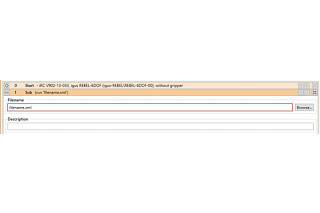

Sub-programs

Sub-programs can be called up with the sub-command. The path to the sub-program file is specified under "File name". It is relative to the subfolder "Programs" of the iRC folder "Data".

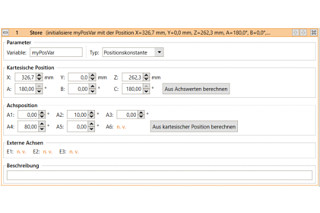

Variables and variable access

Two types of variables are supported in the programs for iRC and TinyCtrl:

- Number variables: These can be used to store integer or floating point numbers.

- Position variables: These can be used to store Cartesian positions and joint positions. Whether such a variable is interpreted as a Cartesian position or joint position depends on the context.

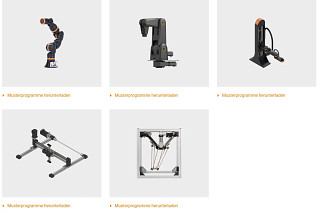

Sample programs

Save time and costs with our sample programs:

Faster integration of the igus® Robot Control for your machines by combining simple components and the igus® sample programs.

- On-demand training videos

- Media centre with many training videos

- Videos for every robot kinematics

- All content available on demand

The igus® Robot Control software

Our software enables simple and intuitive robot programming and control systems, making it easy to get started with automation. Thanks to the modular structure, various robot kinematics, for example delta robots, linear robots and multi-axis joint robots can be controlled. The software can be used to simulate the individual movements of the robot on the 3D surface.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr