Change Language :

How sustainable are motion plastics?

Plastic is a much-discussed material. We know that the high-performance plastics from igus® can make a contribution to protecting resources and the environment and have made this aspect the focus of our business activities. Our declared goal is to be CO₂-neutral with our buildings and production by 2025.

To achieve this goal, we are implementing various measures, some of which are presented on this page and in our brochure "Our path to sustainability". We consider the plastic of our products in three phases:

More about sustainability at igus

Sustainable innovations

Before: Production of plastic

Environmental and climate certifications

We endeavour to achieve continuous improvements in our environmental and energy management. In doing so, we are committed to a sustainable corporate strategy with regard to ecological, economic and social aspects. We have summarised these in our energy and environmental policy.

During: plastic in use

Lubrication-free

27 million tonnes of lubricating grease pollute the environment worldwide every year. Our plastic does not require lubrication.

After: Plastics after their use

Industrial plastics now very easy to recycle

Sustainable behaviour is an important topic that we want to promote in the German economy. To this end, we have created a white paper that explains the most important terms for correct recycling and shows the importance of (recycled) plastic in Germany. In addition, we also present a simple way to recycle technical and industrial plastic and to purchase and sell recyclates in order to complete the circular economy.

Tree planting

Our tree planting activities began in 2019 as Christmas gifts for customers and have since grown into a large number of reforestation projects. We have planted a total of 76,280 trees to date , not just in Germany but worldwide . From saplings to large urban trees, we plant and care for trees and bushes in small and large campaigns. By creating new tree areas, we want to help reduce the C02load in the atmosphere and achieve our self-declared goal of C02neutrality .

Resource conservation projects and initiatives

Sustainable mobility with the igus:bike made from recycled plastic

With our igus:bike and the igus:bike platform, we want to promote sustainable and urban mobility. The bike is made almost entirely of plastic, largely from recycled plastic waste. It is robust, low-maintenance and rust-free and requires no additional lubrication. With the platform, we show the current state of the art and help bicycle and component manufacturers to network and exchange ideas with each other.

Climate-neutral shipping with UPS

As of 1 January 2024, we at igus® Germany have made our shipping more sustainable and introduced a new shipping option: "UPS Carbon Neutral Shipping". Since then, we have been shipping climate-neutrally with UPS and the CO2 emissions generated when shipping our shipments are offset. This is done through recognised, global projects to reduce greenhouse gases, e.g. by protecting the rainforest in Brazil, through wastewater treatment in Thailand or through methane recovery in the Netherlands.

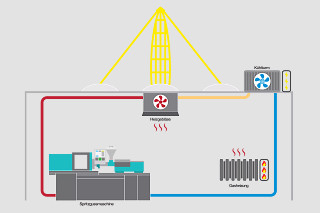

Our heating concept with waste heat from production

Heating with gas, is that necessary? A lot of heat is generated in the production process, surely there must be something we can do with it? How can we manage to utilise the waste heat? A team of igus® engineers asked themselves this question and started to try it out. The result: the concept for a heating system that utilises the waste heat from the machines. The plan was to stop heating buildings at the Cologne site with gas and to make the concept freely accessible to engineers and mechanical engineers, in other words: the industry. We call it MHRS - Machine Heat Recovery System.

Left: rubbish washed ashore in the devices; right: after collection

Plastic Fischer - against plastic waste in rivers

8 to 12 million tonnes of plastic end up in the oceans every year, mostly via rivers. Plastic Fischer starts right here and collects the waste in the rivers, which is cheaper than fishing from the sea. How does the project work? People on site fish the rubbish out of rivers using equipment and receive a regular income in return. The collected plastic waste, which is usually categorised as non-recyclable, is sent to thermal recycling plants: It is incinerated with energy recovery. igus® finances the collection of a total of 10,000 kg of plastic waste. This has provided at least 34 people in Kanpur and Mangalore (India) with a regular income for the duration of the collection, with helpers joining in on some days.

Rhine octopus - igus® supports floating waste trap

Every day, one tonne of waste floats down the Rhine into the North Sea. An immense amount. The Cologne-based association K.R.A.K.E. has been organising waste collection campaigns in and around the Rhine for years. They went a big step further in September 2022 with the floating litter trap. The construction, modelled on the London model, is a passive trap into which floating rubbish drifts. The rubbish octopus is emptied regularly by the club members and the rubbish is collected on land. In cooperation with the University of Bonn, this waste is scientifically analysed in order to conduct a long-term study on plastic waste in the Rhine.

clean igus® - our measures to avoid plastic waste

In the past, it often happened with our injection moulding machines that new parts did not end up in the collection containers, but on the floor - and therefore in the waste. The amount of waste accumulated due to the large number of productions and the large number of machines. By optimising our machines and conveyor belt in various ways, we were able to reduce the waste rate by 21% in 2021 (production waste + processed material): Gaps at transitions were closed with magnetic foils, machines and collection boxes were fitted with metal sheets and covers or lids, conveyor belts were centred and fixed in place, brushes and guide plates steer parts into the correct path, floor markings and stop wedges ensure the correct trade show stand.

Using shore power to combat pollutant emissions in container harbours

Running diesel generators from container ships in harbours are a serious problem. Particulate matter, nitrogen and sulphur oxides as well as CO2 emissions are released into the environment and atmosphere by the tonne. With the iMSPO mobile power socket, we created the possibility in 2022 for container ships to be supplied with shore power easily, quickly and, above all, flexibly. If this is then also "green", the path to the "zero-emission port" is clear.

Resource-saving measures around the world

Update on the path to climate neutrality

In 2021, we caused 31.2% fewer CO2 emissions than in 2020. This figure relates to Scope 1 and Scope 2 emissions. The switch to green electricity in mid-2021 and to climate-neutral gas in October 2021 played a major role here.