Change Language :

Detect cable stress early ... better and more accurately than ever before

NEW with visual status display: i.Sense CF.D module recognises transmission problems with heavily loaded bus cables at an early stage and determines the length of the predicted risk area for the first time.

Tech up

- Monitoring the data transmission quality

- Determination of the distance to the overloaded line area

- Multifunctional control cabinet module with OLED display for key line parameters

Cost down

- Visual status display without extra tools or software costs

- No time-consuming troubleshooting thanks to range finder

- Indicator for timely line replacement - prevent unplanned system downtimes

Proof

- Ongoing test series in the industry's largest test laboratory for dynamic line applications

Sustainability

- No sacrificial veins necessary

- Condition-based maintenance avoids premature product replacement

How line monitoring works with i.Sense CF.D explained simply in the video:

Intelligent condition monitoring successfully realised

i.Cee in practice

When do I need smart line monitoring like i.Sense CF.D?

Other smart solutions for cable monitoring

No additional module is required for condition monitoring (i.Sense) using chainflex® cable. The system can be operated without additional software during integration and networking. In these cases, chainflex® cable takes over 3 possibilities of condition monitoring.

- Tensile and shear force measurement via the cable (CF.P)

- Measurement of the electrical specification of a cable (CF.Q)

- Measurement of the transmission quality (CF.D)

Integration into your own network environment

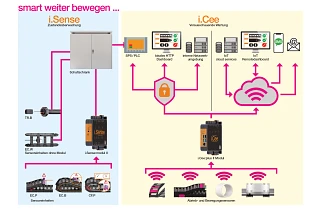

As part of the i.Sense condition monitoring system from smart plastic, all i.Sense CF.D data can also be analysed in the control cabinet module i.Cee. This can then be used to digitally control the entire alarm and escalation management of the system.

The i.Cee module also offers numerous integration options in predictive maintenance concepts. From preventive service management, which schedules regular maintenance depending on usage, to location-independent fault management, which immediately reports any unforeseen changes via various mobile channels. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Overview smart plastic

Insight into the complete igus® product portfolio for Industry 4.0

Content overview of this free brochure:

- Condition Monitoring (i.Sense)

- Systems for condition monitoring

- Advantages of condition monitoring systems

- Application examples of condition monitoring

- Predictive maintenance / predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr