Change Language :

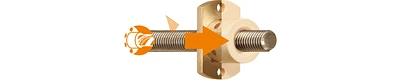

Reduce costs with drylin® lead screw technology

50.9% more favourable compared to metal sliding thread nuts

Quick and easy online calculation

Find out in just a few minutes how long our plastic-lead screw nuts will last in your application - and then select the thread system with the best price-performance ratio. Customised for your application.

Free dryspin® sample

Your own sample thread system with bundled information

- Lubricant- and maintenance-free

- Higher efficiency

- Longer service life due to asymmetry

- Resistant to media

- Low-noise, vibration-free running thanks to rounded tooth geometry

- Service life can be calculated online

Applications with cost-effective solution

DIY beer lift

- What was needed: effortless ascent and descent with corresponding load, low labour costs

- Requirements: maintenance-free, lubrication-free, withstands high torques, weather-resistant, easy assembly, cost-effective, fast procurement

- Products used: dryspin® lead screw nut DST-JSRM-2220DS10X25 and threaded spindle DST-LS-10X25-R-ES

- Success for the customer: Stability of high torques, no lubrication and therefore 100 % maintenance-free, up to 30 % longer service life than conventional lead screws and no problems due to weather conditions

Do you need further cost comparisons for your metal or plastic thread systems in order to identify your savings potential? We will be happy to advise you.

Tech up. Cost down. Change now!

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr