Change Language :

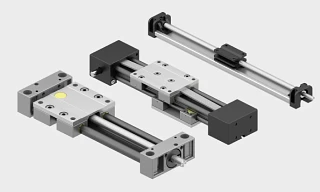

Modular drylin drive technology

Lubrication-free linear axes with lead screw, toothed belt and gear rack

The drylin drive technology offers lubrication-free linear axes that are driven with a lead screw, toothed belts or gear racks. Both electric and manual drives via hand wheels or electric motors possible. In addition to numerous standard designs, igus also offers linear drives for special requirements, e.g. lightweight and ready-to-install linear axes made of plastic or solid stainless steel linear modules for heavy loads. The drive systems are characterised by a long service life, precision and high reliability. The drylin drive technology is also dirt-resistant, lightweight, quiet and suitable for almost all applications and industries around the world. All linear modules can be customised to your requirements in our drive technology configurator .

Our linear axis & accessories at a glance

All of our linear drives from igus drive technology do not require the use of external lubricants. The movement of the linear modules is realised either via lead screws, toothed belts or gear racks. We offer you suitable solutions for the most individual applications.

Drive technology configurator

Customised linear axes according to your requirements

Configure your customised linear axis now. Simply accurate to the millimetre and ready to install.

When do I use which drive for my system?

Lead screw drive

Lead screw drives offer high load capacity and are ideal for applications where precision and force transfer are important. They are well suited for vertical movements and heavy load applications. The lead screw drive ensures strong and accurate positioning.

Toothed belt drive

Toothed belt drives are ideal for applications that require high speeds and dynamic movements. They offer high acceleration and repeatability. The toothed belt drive enables low-friction and quiet movement.

Rack and pinion drive

Rack and pinion drives offer a combination of high speed, precision and load capacity. They are particularly suitable for long distances and horizontal movements. The rack and pinion drive allows smooth and strong movement along the axis.

Benefits of drylin drive technology

Application examples of drive technology

Further information on drylin drive technology

Frequently asked questions from our customers

Our different linear drives offer a wide variety of advantages for all kinds of applications.

- Toothed belt drives offer high acceleration and repeatability. They are therefore particularly suitable for pick-and-place machines, packaging systems, 3D printers and other applications where fast and precise positioning is required.

- Lead screw drives offer high load capacity, precision and power transmission. They are therefore well suited for CNC milling, laser marking machines, machine tools and robotics applications. The lead screw drive ensures strong and accurate positioning.

- Rack and pinion drives offer a combination of high speed, precision and load capacity. Applications for linear drives with gear rack can be found in material handling, packaging, assembly line automation, and other areas where rapid, accurate positioning over longer distances is required.

Yes! The drylin® E linear drives do not require additional lubricants and are therefore particularly resistant to contamination. Our drive systems can even be used with sand, swarf and dust.

Yes! The drylin® E linear drives do not require additional lubricants and are therefore particularly resistant to contamination. Our drive systems can even be used with sand, swarf and dust.

We have put together a selection of narrow and flat linear units for particularly small installation spaces. You can choose from linear axes with lead screw or toothed belt drives, which can be driven manually or by motor.

You can also use our ready-to-install linear modules for motorised lead screws drives. Thanks to the direct lead screw support in the motor, which is connected directly to your new linear module and therefore does not require a motor flange or coupling, up to 35% installation space can be saved with the drive elements, depending on the version.

At igus you will find numerous technical accessories for manual and electric drives. Our portfolio ranges from operating elements such as position indicators and hand wheels up to fastening and assembly accessories and individual electric motors in a wide variety of designs. Here you will find an overview of all linear module accessories

For very long travels, we offer an endless gear linear module. This is based on a rack and pinion drive and can be expanded almost endlessly using an interlocking carriage profile. Several carriages can also be controlled in parallel or independently of one another.

Drive technology configurator

Customised linear drives according to your wishes

With the online configurator for drive technology, you can enter your requirements and receive linear drives with lead screw, toothed belt or gear rack and pinion drive, which you can configure according to your needs. Motors, motor control systems and other accessories for your linear drives can also be ordered directly.

- Quick and easy configuration

- Optional accessories

- Detailed parts list

- Fast delivery* (ready to ship from 48 hours)

Consulting

I look forward to answering your questions

Michael Hornung+49 2203 9649 0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr