Change Language :

Test reports of the servo cables

Discover all our service life test reports for our servo cables here.

Servo cable CF887.15.15.02.01

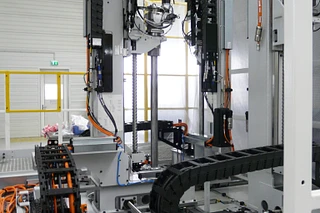

Using the CF887 in practice

Servo drives can be found everywhere, for example in linear robots used in the packaging industry. The logistics halls in which these devices are found are usually well tempered, oil and other influences are also rare to non-existent, only the speed and the bend radius must not demand too much from the cable. The PVC outer jacket of the CF887 is flexible and abrasion-resistant, made for permanent movement in the energy chain and also very economically attractive. Thanks to the guaranteed service life, maintenance can be planned well and failures due to e.g. corkscrew, no longer occur.

Servo cable CF21.25.15.02.02.UL

Using the CF21.UL in practice

Wood dust and shavings are common in the furniture industry. These conditions are particularly prevalent in the use of woodworking machines. They are characterised by a high versatility of processing functions: milling, drilling, sawing. All of these machines utilise drive systems and thereby servo cables. When it comes to tight installation spaces or long distances on gantries, the design with an inner jacket guarantees reliability.

Servo cable CF270.UL.D

Using the CF270.UL.D in practice

Servo motors have become indispensable these days. Many manufacturers with different requirements are on the market. However, conventional cables reach their limits, especially in moving applications. A classic example of the use of servo motors is in cutting and machining centres. In these systems, the cables are not only moved very frequently and in tight radii, but also have to withstand a wide range of environmental influences. Swarf, oil, water and cleaning agents are the order of the day. The PUR material of the CF270 can withstand all of this. Thanks to its oil resistance and notch-resistant specification, the cable can be used for its full service life at temperatures from -20 to +80°C.

Servo cable CF270.UL.100.01.D

Use of the CF270.UL.D in practice

The aim of the test was to determine the service life of the servo cable in the energy chain. The CF270 is a so-called "spindle cable". This type of single-core cable is used in high-performance turning centres or CNC machines, for example. In both examples, the power supply is a challenge, as the applications sometimes require the creation of high-precision and very complex moulds. In addition, the cable in such machines is located directly on the workpiece and must therefore be highly resistant to metal chips and, above all, the oils used. Thanks to the PUR outer jacket, this cable fulfils these criteria and can also guarantee fail-safe use thanks to its tested service life.

Servo cable CF27.25.15.02.01.D

Using the CF27.D in practice

Oil, tight bend radius, chips, fast and frequent movements. A modern milling machine is a veritable torture chamber for cables. Thanks to its notch-resistant PUR outer jacket, the CF27.D is ideally equipped to withstand oil and swarf. The TPE inner jacket and the flat braid angle of the shield make even the smallest bend radius of up to 7.5xd easy for this servo cable. Suitable in cross sections of all common motor sizes, whether as a single core, without a control pair or with one or two control pairs. Various approvals, such as UL, also allow worldwide use.

Servo cable CF29.25.15.02.01.D

Using the CF29.D in practice

Cables of the CF29.D family are frequently used in storage and retrieval machines (SRMs). There they are used in the mast's hoisting gear. High dynamics and cold environments pose major challenges for the components used. They have to withstand extremely low temperatures, e.g. in cold storages.

Consulting

I look forward to answering your questions

Katharina Wielpütz+49 2203 9649 7082Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr