Change Language :

Energy chains Wiki

Popular topics

The energy chain (also energy chain, e-chain® or drag chain) is a machine component that guides and protects flexible cables and hoses . Its protection reduces downtimes and increases the service life of cables and hoses. Save time and money when purchasing and using energy chains from igus®.

Representation using the example of an E4Q chain link. Some energy chains deviate from this representation.

Elements of an energy chain

An energy chain consists of several interconnected chain links. The energy chain is terminated by mounting brackets on both sides. A chain link has the following elements:

- Upper crossbar (for tubes: lid)

- Side part - inner and/or outer link

- Lower crossbar (for tubes: bottom)

- Separator for vertical separation

- Shelf for horizontal interior separation

Design energy chains easily

Basics and calculations

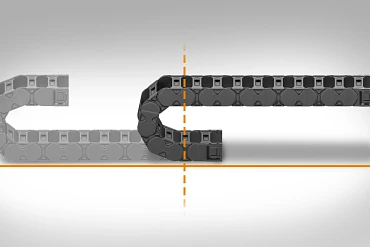

The fixed end in the middle of the travel path is always the most favourable solution. This is how the chain length is calculated.

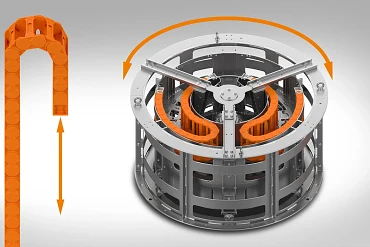

Types of movement

From unsupported applications to circular movements and zig-zag applications.

Filling rules

General filling rules for cable and hose in energy chain.

Strain relief

Ideally, the cable/hose should be strain-relieved at both ends of the energy chain.

Environmental influences (technical environment)

Material specifications: Material igumid®, cleanroom and ESD, environment with dirt accumulation, chemical resistance.

Technical terms and definitions

Here you will find an overview of all abbreviations and formulae relating to the energy chain.

FAQ - frequently asked questions

We recommend the Product filter in the shop. Simply filter by type of movement in the shop and narrow down the results based on the dimensions.

With the energy chain configurator "e-chain® expert" you can put together your customised, ready-to-connect energy chain system in just a few steps.

Simply use our Service life calculatorto calculate the expected service life of the energy chain.

Through the use of our i.Sense sensors you receive a well-founded status report of your energy supply at any time in real time.

Travelling distances of 1,200 m and more are possible with roller chains. Read more.

As a rule, the standard temperature range for plastic energy chains is -40°C to +130°C, short term +170°C.

Our design award-winning cable chains have been specially developed for offices and furniture. For example, igus offers the ZF14 or OCR cable chain for organised cable guides at the desk. Fastening options: magnetic, screwed and glued.

One detailed list provides information on the resistance of the igus® materials igumid® G, TE and NB to many chemical substances.

Yes, plastic-energy chain with the Material igumid® HT are resistant to hot chips up to + 850°C.

Yes, with the system autoglide you can realise travel distances of up to 80 m without a guide trough.

Yes, all igus energy chain materials can be used for continuous use down to -40°C.

Yes, all Energy chains made from conductive ESD material can be found here.

Yes, we recommend the TH3 energy chainwhich has been specially developed for the food and beverage industry.

Yes, with igus® Plastic energy chains it is possible to save up to 57 % and with chainflex cables up to 17 %. Tech up now and improve energy efficiency.

With our i.Cee system For predictive maintenance, you are shown the optimum maintenance time in real time at all times, depending on the actual movement profile and the current status of your energy supply.

Why energy chains from igus?

Consulting

I look forward to answering your questions

Dieter Reitz+49 2203 9649 7070Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr