Change Language :

Energy supply systems for final vehicle assembly

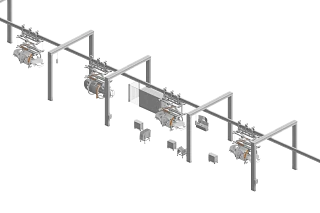

Energy safely guided in lightweight and robust e-chain®

Final assembly is where the finishing touches are applied to the production chain. However, the demand for trouble-free processes is no less stringent here than at the start of production. Manipulators, which in this step often support people during production, should be easy to move. Here, energy chains made of plastic, light but robust, are just right. With supporting rollers, even long distances can be travelled steadily and reliably.

Success stories

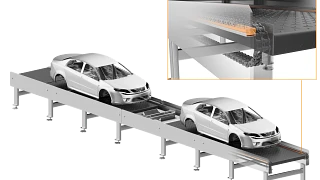

NEW: igus® glide bar for chain conveyors

In addition to the drive and the roller chain, the glide bar is an indispensable element of the chain conveyor. The glide bar carries the applied loads and enables a continuous drive thanks to its low coefficient of friction.

Our glide bars made of iglidur® bar stock are designed for the high loads caused by car bodies. And of course you also benefit from our typical advantages here: All our products are maintenance-free and have a low coefficient of friction.

Our service starts even before installation:

- We plan the optimisation of your system to guarantee maximum service life

- Support in reducing downtime costs and increasing system availability

- Retrofitting your existing machines as a system partner

- Retrofitting condition monitoring or predictive maintenance to igus® products

- Our energy chains are also available as ready-made systems, e.g. e-chain system® for transfer carriages (plug and play)

- After installation: regular inspection and maintenance of your energy chain and condition monitoring systems

- At the end of the life cycle, we take the energy chain back and recycle it

Suitable products

Consulting

I look forward to answering your questions

Andreas Dengler+49 2203 9649 7734Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr