Change Language :

Reliable energy supply and maintenance-free plain bearings for stage technology

Areas of use

Free white paper

Vertical energy supply in stage technology - 6 tips

Like every industry, stage technology has its own specific requirements for machine parts and materials. In this white paper, we give you 6 tips for the selection and design of vertical cable carriers for stage technology

Top products for stage technology

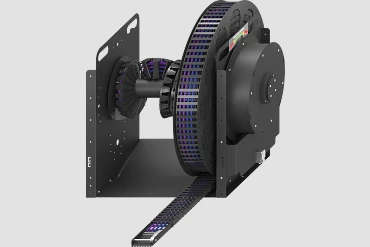

NEW: e-spool microphone 30 metres

- Uninterrupted sound transmission without slip ring

- Cable can be easily replaced

- Simple and space-saving installation, no additional support equipment required

- No manual work at height

- Manufactured in accordance with the DIN EN 17206 standard and DGUV principle 315-390

Cable reel for e-chains without slip ring

With the e-spool, moving stage technology can be supplied with different media without interruption. The system is used for stage platforms, movable lighting hoists or video cubes. The inserted cables are routed through a twisterband so that no slip ring is required. This offers a particular advantage when transmitting data. The length of the reeled energy chain is adjusted by a return spring for a stroke of up to 15 metres and by a motor for a stroke of up to 25 metres and more. Placed on the string floor, in suspended ceilings above the auditorium or in the understage area, the system operates unobtrusively out of sight of the audience.

- All media in one system: Power... data... fibre optic...

- Deflectable energy chain for a wide range of applications

- Quiet and low-vibration

- Simply add or replace cables

- Completely assembled with cables and connectors on request

- Manufactured in accordance with the DIN EN 17206 standard and DGUV principle 315-390

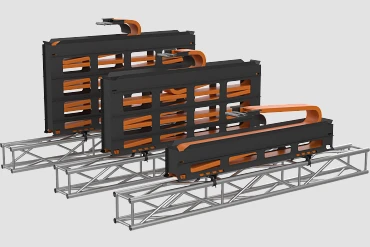

Zig-zag system

As an alternative to the e-spool, we offer the zig-zag system – our classic that has proven itself on the stage for many years (at the Royal Opera in London since 1998, for example). With this space-saving system, different media can be guided together without interruption and with no slip rings. The energy chain unfolds during the stage machinery's vertical movement. For upper stage machinery, the zig-zag box is mounted on the tie rod or truss; in understage machinery, it is mounted on the floor below the podium.

- Quiet and low-vibration

- No tensile load on the cables

- Simply add or replace cables

- All media in one system: Power... data... fibre optic...

- In projects with up to 40 metres of travel and more

Available as a standard complete system with a travel distance of up to 15 metres:

Discover zig-zag as an iSet now

NEW: Low-cost version without guide box

Around 50% weight and cost savings compared to the standard version

Two-component heavy-duty bearings

Our iglidur Q3E multi-component bearings are the right choice for use under very high loads, for example in scissor joints of stage platforms.

- High mechanical strength with low wear

- Cost-effective due to injection moulding production

- Lubrication-free dry running without maintenance

Exhibition stand for stage technology

Experience products virtually - alone or with a guide

Did you miss the last trade show for stage technology? We have the solution. Simply visit our exhibition stand for stage technology in Cologne online.

Successfully in use with our customers

Tested for use in the test laboratory

All products are tested for wear and load capacity under real conditions in the igus test laboratory, the largest in the industry. The results flow into our tools for calculating service life and enable precise predictions to be made about durability.

On request, igus also carries out customer tests to test the use of the products under very individual conditions.

Consulting

I look forward to answering your questions

Michael Berteit

Head of Sales Engineering Projects and Installation Service

+49 2203 9649 7439Write e-mailShipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr