Change Language :

Smart, reliable energy supply in the smallest of spaces

i.Sense ES.B: Intelligent breakage detection on theatre e-spool® guarantees safe movement at all times

3D illustration of the new theatre e-spool® with spring force monitoring

The e-spool® system ...

... the alternative to the cable drum without slip ring

Safely guide many different cables in the smallest of spaces with e-spool®. e-spool® combines two different energy supply systems in a unique way: A standard energy chain is guided by a roller and, thanks to an integrated retaining spring, ensures exactly the right length and tension of the energy supply system at all times. In the starting position, the space-saving energy chain is fully retracted. The twisterband connects the roller to the shaft end block, which serves as an interface to the permanently installed cable.

Intelligent condition monitoring successfully realised

i.Sense from smart plastic in practice

When do I need a smart status sensor like i.Sense BRG?

Smart machine data acquisition as the basis for predictive maintenance concepts

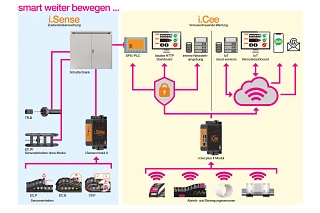

As part of the i.Sense condition monitoring system from smart plastic, all data from the i.Sense Wonderbox can also be analysed in the control cabinet module i.Cee. This can then be used to digitally control the entire alarm and escalation management of the system.

The i.Cee module also offers numerous integration options in predictive maintenance concepts. From preventive service management, which schedules regular maintenance depending on usage, to location-independent fault management, which immediately reports any unforeseen changes via various mobile channels. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

white paper on optimising the overall equipment effectiveness OEE

Differentiates condition monitoring from predictive maintenance

In this free white paper you will learn

- What does condition monitoring (i.Sense) mean at igus®?

- What is predictive maintenance (i.Cee) at igus®?

- What technology is behind both systems

- What do both systems offer for energy supply in the industry

24/7 tension / thrust force monitoring

Condition monitoring system i.Sense EC.P

The smart plastic i.Sense EC.P system (EC = e-chain P = pullforce) provides additional protection for the energy chain by continuously measuring the tensile and shear forces of the e-chain®. If the forces are exceeded, the sensor recognises this, reports it and, if necessary, switches off the system to prevent potentially expensive consequential or total damage to the system.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr