Change Language :

Reduce machine downtime with smart pull/push force detection for e-chains

i.Sense EC.P - Save a lot of money and worry with little effort thanks to smart technology from igus

You have to master immense push/pull forces on energy chains or drag chains. Because where travels and forces increase, so does the risk. Full control including switch-off recommendation is guaranteed by our i.Sense EC.P from smart plastics. These intelligent sensors can be used on any e-chain® - unsupported or gliding - and they even work with changing loads and fluctuating environmental parameters. This significantly reduces your downtime costs and continuously increases overall system effectiveness.

Difficult environment, reliable energy supply - energy chain systems from igus® defy dust and dirt in aluminium oxide production

Free case study

This case study discusses the question asked by almost all design engineers who have to guide hoses as well as energy and data cables in moving applications with long travel distances of over 100 metres:

Which energy supply system is the best for reliability, ease of maintenance and future security, among other things? A motorised cable reel? Or an energy chain?

What is i.Sense EC.P and what does it do for me?

Functionality and advantages

- The EC.P (EC = e-chain P = Pullforce) sensor unit is fitted at one end of the e-chain.

- There, the sensor continuously measures the pull/push forces acting on the e-chain and transmits these via a cable to a top-hat rail module installed in the control cabinet.

- The vast majority of failures are preceded by an increase in force, e.g. due to foreign objects, snow/ice, misalignment, and deformed or loosened guide troughs.

- If the forces are exceeded, the i.Sense EC.P system recognises this, reports it and switches the system off instantly to prevent expensive consequential or total damage.

Installation on container crane ...

... and reactivation after the system is triggered

- We have retrofitted a condition monitoring system to a rail-mounted overhead crane as a complete package.

- If the tensile forces become too high due to damage to the e-chain or external influences, the system can be switched off as a precautionary measure.

- Once the fault has been rectified, the i.Sense EC.P system can be reactivated in just a few steps.

What technical components does i.Sense EC.P consist of?

The technology for smart push/pull force monitoring in detail

How are i.Sense EC.P sensors mounted on the chain?

How is the i.Sense EC.P module connected?

In addition to the installation instructions, there are also detailed operating instructions for all our smart plastics systems. These guide you step by step through all the necessary operating elements:

- Safety instructions

- Installation & connection planning

- Configuration & calibration

- Operating statuses

- Troubleshooting

i.Sense EC.P - intelligent push/pull force monitoring successfully implemented

Download a free case study

When do I need a smart condition monitoring system like i.Sense EC.P?

When regular maintenance work requires complete production shutdown ...

When motion anomalies cannot be detected by humans in time ...

If plants or machines need to be monitored frequently or continuously ...

If energy supply system travels are difficult to access or view ...

If maintenance work poses a health or safety risk ...

If maintenance costs are to be reduced and service life extended ...

Various scenarios were examined in detail in a break-even analysis

When does the purchase of i.Sense EC.P pay off?

The financial benefits of safety systems are often difficult to assess, especially because the initial investment in a modern condition monitoring system increases costs instead of reducing them. So we performed a break-even analysis for the entire utilisation period based on practical experience in an automotive production hall.

Given the average cost per working hour for all typical maintenance expenses in the German manufacturing industry (EUR 41.60), an EC.P system reaches its benefit threshold in just the third year of use, even by a conservative estimate (regular case).

Personalised advice is guaranteed

Do you also have a crane or system on which you would like to monitor the tensile forces of the e-chain in order to increase system safety?

If so, feel free to get in touch with me.

I look forward to hearing from you!

► Request contact online

► Make an appointment

► Expert support by phone or via the video chat function

i.Sense EC.P as the basis for predictive maintenance

Always the optimum maintenance strategy with smart plastics from igus

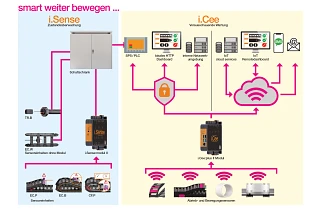

For a solid foundation for predictive maintenance concepts, you need a smart network of individual condition monitoring systems, such as i.Sense EC.P. At igus, everything related to preventive maintenance falls under the term i.Cee. Similarly, i.Sense encompasses all condition monitoring systems.

The central element here is the i.Cee software,which, combined with i.Sense condition monitoring sensors on the energy chain, the plain bearing bushing, or a linear carriage, transform stock products into smart ones. This upgrade creates the capability of determining maximum service life and optimal maintenance intervals in real time based on real usage data.

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr