Change Language :

Smart Factory

Low Cost Automation for the fully automated production of the future -smart plastic for the intelligent system control of the future

AGV robot as a complete system

- Plug & play integration between AGV and robolink® DP

- Autonomous support for employees

- Save time and money thanks to ready-to-use integration with software and hardware

- Expected ROI after 12-18 months

- Use of low-cost automation components

- Available on RBTX®, the igus® marketplace for low-cost robotics

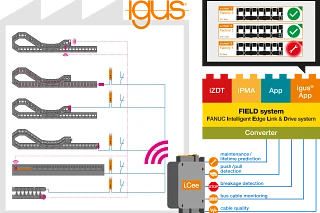

Intelligent system monitoring with the Fanuc FIELD system and smart plastic

The international robot manufacturer Fanuc offers its open industrial IoT platform "FIELD system" to analyse data from machines and systems centrally. The system can connect production machines from all manufacturers via a local network topology, enabling comprehensive data analysis of the entire process chain. Apps from Fanuc as well as third-party providers such as igus® are used in this infrastructure. With this "smart plastic - i.Cee" app, maintenance technicians can monitor the condition of their igus® components, for example energy chain and cable, in the FIELD system and plan maintenance with foresight.

Industrial and service cobots

Build your own cobot

- 25-50% lighter than conventional multi-axis robots thanks to the use of igus® high-performance polymers

- Tested in the Low Cost Automation laboratory

- Controllable with the igus® Robot Control, a control system for all robots

Extend the workspace of any robot

- Suitable adapter kits for igus® robots, Universal Robots, Epson, Omron, Franka Emika, Doosan, Yuanda Robotics and many more.

- For the flexible use of robots in the workspace

- Ready-to-install linear axis as 7th axis in robotics

robotics - toothed belt axis ZLW-20 from the standard

linear construction kit - Fast control via digital I/Os

How does predictive maintenance work?

Only the intelligent networking of the individual components creates a solid basis for predictive maintenance concepts. At igus®, everything about predictive maintenance is summarised under the term i.Cee ("I see ahead").

The central element is the i.Cee software. This software, in conjunction with sensors on the energy chain, the plain bearing bush or a linear slide, turns the products available from stock into smart products. It makes it possible to determine the maximum service life of your igus® product and the i.Cee system also indicates the perfect service time. Algorithms adjust the service life and the service time according to usage. With the software we provide, a few sensors and the new communication module i.Cee:plus II, standard products can be turned into a smart energy supply or intelligent plain bearings in no time at all.

One control system for all robots

- Preconfigured projects for all igus® single axes, SCARA, and AGV

- Test the software in advance free of charge

- Intuitive control and programming environment with free 3D user interface

- Remote access of the user interface to the computer via TCP/IP possible

- Options: Grippers can also be graphically integrated into the software

Examples of fully automated production

Vertical farming with Low Cost Automation

- High cost savings, resulting in a fast ROI

- Flexible customisation of robot tasks

- Lubricant and maintenance-free; no contamination of the products

- Dirt and corrosion-resistant components

- FDA-compliant components

Industry 4.0: successfully implemented in practice

▲ Tech up

- Extension of the maximum service life

- Increasing the overall system efficiency

- Integration into Industry 4.0 / IIoT concepts

▼ Cost down

- Reduce maintenance costs through early warnings

- Eliminate unplanned downtimes

- Reduce inventory costs

Intelligent solutions for condition monitoring and predictive maintenance

Consulting

I look forward to answering your questions

igus® GmbH+49 2203 9649-0Write e-mail

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr