Change Language :

smart plastic MWS: customised real-time monitoring has never been easier

The smart plastics mini wear sensor (MWS) is used to record the percentage of abrasion on moving system parts in order to avoid possible operational failures at an early stage.

IoT expert Richard Habering explains the use and benefits of the new low-cost sensors.

Intelligent condition monitoring successfully realised

i.Sense from smart plastic in practice

When do I need a smart status sensor like i.Sense BRG?

Live condition monitoring in any position(s)

i.Sense BRG for everyone

Not just for farmers, but for every machine operator, a defective bearing can spoil the working day and the mood. Machine failures and downtimes are among the biggest cost drivers in the industry. It is therefore important for maintenance staff to prevent unplanned downtime in good time.

Smart bearing products from igus® are therefore particularly suitable for particularly sensitive or hard-to-reach areas of a machine, as the condition of the bearing can be checked at any time. With the help of the sensor, every wear-resistant part of a machine can be monitored remotely - from which many other motion plastics also benefit.

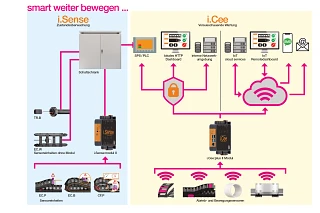

Integration into your own network environment

As part of the i.Sense condition monitoring system from smart plastic, all data from the new i.Sense BRG mini sensor can also be analysed in the i.Cee control cabinet module. This can then be used to digitally control the entire alarm and escalation management of the system.

The i.Cee module also offers numerous integration options in predictive maintenance concepts. From preventive service management, which schedules regular maintenance depending on usage, to location-independent fault management, which immediately reports any unforeseen changes via various mobile channels. All information is aggregated in a modern dashboard, online or offline in the local network, depending on the customer's requirements.

Overview smart plastic

Insight into the complete igus® product portfolio for Industry 4.0

Content overview of this free brochure:

- Condition Monitoring (i.Sense)

- Systems for condition monitoring

- Advantages of condition monitoring systems

- Application examples of condition monitoring

- Predictive maintenance / predictive maintenance (i.Cee)

- Systems for predictive maintenance

- Advantages of predictive maintenance systems

- Application examples for predictive maintenance

- Data flow in modern smart factory concepts

Consulting

I look forward to answering your questions

Shipping and consultation

In person:

Monday to Friday from 7 am - 8 pm.

Saturdays from 8 am- 12 pm.

Online:

24h

WhatsApp-Service:

Montag – Freitag: 8 – 16 Uhr