Change Language :

iglidur® W360 - material data

The most important specifications at a glance

Low moisture absorption and high temperature resistance result in an extremely broad range of uses for this extremely wear-resistant material.

| Descriptive technical specifications | ||

|---|---|---|

| Wear resistance at +23°C | - 🟧 🟧 🟧 🟧 ⬜️ + | More information on wear resistance |

| Wear resistance at +90°C | - 🟧 🟧 🟧 ⬜️ ⬜️ + | |

| Wear resistance at +150°C | - 🟧 🟧 ⬜️ ⬜️ ⬜️ + | |

| Sliding property | - 🟧 🟧 🟧 🟧 🟧 + | Coefficient of friction, dynamic, against steel: µ 0.07 - 0.21 |

| Wear resistance under water | - 🟧 🟧 ⬜️ ⬜️ ⬜️ + | |

| Media resistance | - 🟧 🟧 🟧 🟧 ⬜️ + | More information on media resistance |

| Resistant to edge pressures | - 🟧 🟧 🟧 🟧 ⬜️ + | |

| Resistant to shock and impact loads | - 🟧 🟧 🟧 🟧 ⬜️ + | |

| Dirt resistance | - 🟧 🟧 🟧 🟧 ⬜️ + |

Temperature

The temperature resistance makes iglidur W360 a very universal material for plain bearings in various industries. Short-term application temperatures of up to +200°C are permissible. Additional protection is required for temperatures above +90°C.

Temperatures, coefficient of thermal expansion

| min. application temperature | Upper application temperature, long-term | Upper application temperature, short-term | In addition secure axially from |

|---|---|---|---|

| -40°C | +180°C | +200°C | +90°C |

Permissible surface speeds

iglidur W360 plain bearings are well suited for low and medium speeds in both rotating and oscillating applications. Linear movements can also be supported well with iglidur W360.

Surface speeds of various iglidur materials

| Maximum surface speeds [m/s] | Rotating | Oscillating | linear |

|---|---|---|---|

| Long-term | 1.2 | 0.9 | 3.0 |

| Short-term | 2.7 | 2.0 | 5.0 |

Permissible pv values

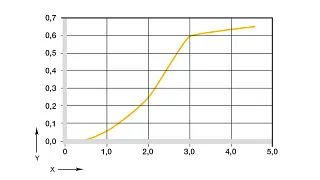

Diagram 01: Permissible pv value for iglidur W360 plain bearing in dry operation against a steel shaft, at +20°C

X = surface speed [m/s]

Y = pressure [MPa]

pv value, max. (dry)

MPa · m/s

0.35

<a 0="[" 1="o" 2="b" 3="j" 4="e" 5="c" 6="t" 7=" " 8="O" 9="b" 10="j" 11="e" 12="c" 13="t" 14="]" href="/de-de/website/gleitlager/wiki/p-x-v-wert-und-schmierung" uuid="f16b1d8b-0ff1-4a28-951c-3fbeec74eafd" target="_self">Information on pv value and lubrication

Mechanical specifications

The compressive strength of iglidur W360 plain bearings decreases with increasing temperatures. Diagram 02 illustrates this relationship. At +180°C, the permissible surface pressure is still 10MPa. The maximum recommended surface pressure represents a mechanical material parameter. Conclusions on the tribology cannot be drawn from this. iglidur W360 plain bearings are suitable for a wide range of loads. Diagram 03 shows the deformation under temperature. The behaviour of the materials under short-term stress is shown here.

Friction and wear

The coefficients of friction of iglidur W360 in dry operation against steel is in a very good range. They remain very constant at a low level over the speed. Diagram 04 illustrates this relationship. As the load increases, the coefficient of friction falls sharply, especially up to approx. 15MPa (diagram 05).

Coefficients of friction against steel (Ra = 1μm, 50 HRC):

| iglidur W360 | dry | Greases | Oil | Water |

|---|---|---|---|---|

| Coefficient of friction μ | 0.07 - 0.21 | 0.09 | 0.04 | 0.04 |

Shaft materials

In the case of iglidur W360, the surface roughness of the shaft in the range up to 1.6MPa has practically no influence on the coefficient of friction (diagram 06). Diagram 07 shows an extension of the results of tests with different shaft materials. iglidur W360 plain bearings are suitable for all mating surfaces. In rotation at 1MPa load, aluminium hc, Cf53 and the stainless steel shafts stand out. The picture is similar for other loads or in pivoting movements. If your intended shaft material is not included in the test results presented here, please contact us.

Moisture absorption

The moisture absorption of iglidur W360 is low and can be neglected when used in humid environments. However, with a complete saturation of 1.6%, use under water is only possible to a very limited extent.

Chemical resistance

All data at room temperature [+20 °C], + resistant 0 conditionally resistant - non-resistant

| Chemicals | Resistance |

|---|---|

| Alcohols | 0 to - |

| Greases, oils without additives | + |

| Hydrocarbons | + |

| Fuels | + |

| Strong alkalines | + |

| Strong acids | 0 to - |

| Diluted alkalines | + |

| Diluted acids | 0 to - |

Installation tolerances

iglidur W360 plain bearings are standard bearings for shafts with h-tolerance (recommended minimum h9). The bearings are designed for press-fit into a housing machined to a H7 tolerance. After being assembled into a nominal size housing, the inner diameter automatically adjusts to the E10 tolerances.

Important tolerances according to ISO 3547-1 after press-fit:

| Diameter d1 [mm] | Housing H7 [mm] | iglidur W360 plain bearing E10 [mm] | Shaft h9 [mm] |

|---|---|---|---|

| up to 3 | +0.000 +0.010 | +0.014 +0.054 | -0.025 +0.000 |

| > 3 up to 6 | +0.000 +0.012 | +0.020 +0.068 | -0.030 +0.000 |

| > 6 up to 10 | +0.000 +0.015 | +0.025 +0.083 | -0.036 +0.000 |

| > 10 up to 18 | +0.000 +0.018 | +0.032 +0.102 | -0.043 +0.000 |

| > 18 up to 30 | +0.000 +0.021 | +0.040 +0.124 | -0.052 +0.000 |

| > 30 up to 50 | +0.000 +0.025 | +0.050 +0.150 | -0.062 +0.000 |

| >50 to 80 | +0.000 +0.030 | +0.060 +0.180 | -0.074 +0.000 |

| >80 to 120 | +0.000 +0.035 | +0.072 +0.212 | -0.087 +0.000 |

| > 120 up to 180 | +0.000 +0.040 | +0.085 +0.245 | -0.100 +0.000 |

Buy iglidur W360 products in the online shop

- Large selection of moulds and materials

- Available within 24 hours

- No minimum order value

- No minimum order quantity

Typical application areas

Consulting

I look forward to answering your questions

Shipping and consultation

In person

Monday to Friday: 8 am – 8 pm

Saturday: 8 am – 12 pm

Chat-Service

Monday to Thursday: 8 am – 6 pm

Friday: 8 am – 5 pm

WhatsApp-Service

Monday to Thursday: 8 am – 4 pm