Change Language :

Application points for bearing technology in lorries

Find the right bearing for every installation position and requirement

Friction, wear, vibrations, moisture and dirt are just some of the many requirements that need to be taken into account when choosing the right bearing for commercial vehicles. Whether small vans or articulated lorries, dump trucks or trailers: the challenges can vary greatly. Using the example of a lorry with semi-trailer, we show which bearing materials are best suited to which installation points and what needs to be considered when making a choice.

Exterior

Cab tilting device | wind deflector system | exterior mirrors | cab damping | tipping hydraulics | side roller tarpaulins | rear wind deflector | door locking system | Front spoiler | Front axle | Flap hinge | Trailer support | Brake system | Leaf suspension | Tail lift | Door

hinge Interior and engine

compartment Steering linkage | Shift lever | Gearbox | Seat adjusters

Exterior

Cab tilting mechanism

Plain bearings installed in the tilting mechanism must be able to withstand high edge loads over the long term. As moisture and particles can easily enter the region behind the radiator grille, the products must also be resistant to corrosion and dirt.

Suitable storage material:

iglidur P210

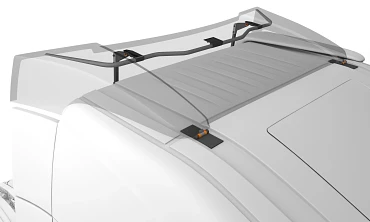

Wind deflector system

The small but aerodynamically important wind deflectors are primarily exposed to wind forces and dirt loads. In addition, external weather influences such as moisture are the determining factors that determine the choice of the right storage technology.

Exterior mirrors

Some of the few bearing points that are not characterised by high edge loads are located on the side mirrors. Here, other aspects such as ease of installation and absolute freedom from maintenance take centre stage. So that the driver can concentrate fully on the road, the bearings must also not make any noise or vibrations.

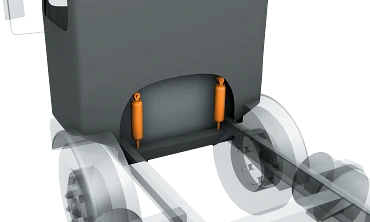

Cabin damping

The use of oil requires a high level of media resistance from components located near hydraulic dampers. Stronger vibrations also occur in this area, which must also be absorbed by the bearing points.

Suitable storage material:

iglidur H4

Tipping hydraulics

In dump trucks, the bearings installed on the telescopic cylinder carry a lot of weight. As with many pivot points in commercial vehicles, high forces act here due to edge pressure. Due to the proximity to the loose bulk material transported in the skip, a high dirt and dust load must be taken into account when selecting the bearing.

Suitable storage material:

iglidur G

Side roller tarpaulins

As the forces involved in the movement of side roller tarpaulins on lorries are low, other factors play a role in the choice of the right plain bearing, such as a low coefficient of friction or high media resistance. Also important: In order to allow the smoothest possible movement, the bearings in the carriage must be able to move even with low drive forces.

Suitable storage material:

iglidur P210

Rear wind deflector

The small but aerodynamically important wind deflectors are primarily exposed to wind forces and dirt loads. In addition, external weather influences such as wetness are the determining factors that determine the choice of the right bearing.

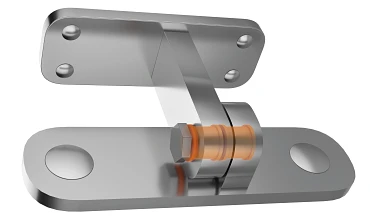

Door locking

Compared to many other installation points in commercial vehicles, plain bearings installed in the espagnolette lock must operate particularly clearance-free. Other requirements are determined by external environmental factors: Freedom from corrosion and high resistance to dirt are required.

Front spoiler

One of the few places in the lorry where no plain bearings are used for movement is the variable front spoiler, which can be lowered while driving. The aerodynamic advantage is achieved with threaded spindles, which must be splash and salt water resistant and corrosion-free.

Suitable product:

dryspin® Threaded spindles with iglidur® J-lead screw nut

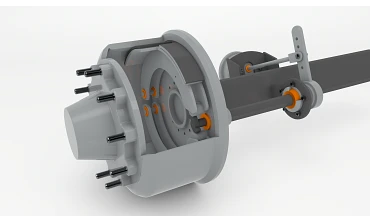

Front axle

The front axle is a crucial element for vehicle stability and safety. Plain bearings used here must be able to withstand high edge loads, should be dirt and oil-resistant and ideally have vibration-damping specifications.

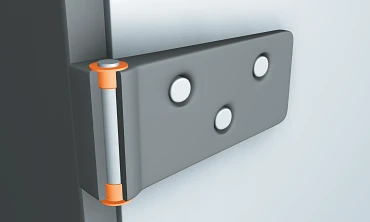

Flap hinge

Doors and drop sides of commercial vehicles are not protected against external influences such as temperature fluctuations, moisture or dirt. Hinges and their bearings in particular must also be able to withstand high static loads over the long term.

Suitable storage material:

iglidur G

Trailer support

bearing in lorry supports must be able to withstand high static loads. At the same time, moisture and dirt must not be a problem. Robust plain bearings with low moisture absorption are the right choice here.

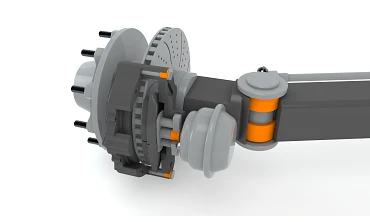

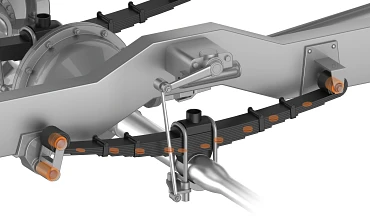

Brake system

The demands on bearing in the brake system are particularly high: high temperatures and loads, constant contact with dirt, water and lubricant must not lead to any loss of function.

Leaf spring suspension

Due to the high friction generated in the area of the leaf springs, the numerous bearing points must also be able to absorb high loads. Low clearance and low static friction are also desirable here, although the bearings must also be able to withstand high edge loads without any problems.

Tail lift

As they have to carry forwarders and their heavy freight without any problems, particularly robust slide bearings designed for high edge loads must be used here. The tail lift bearings must be able to cope with dirt at the exposed points as well as moisture and wetness.

Door hinge

Due to their exposed position on commercial vehicles, doors and drop sides are not protected from external influences such as cold, moisture or dirt. Hinges and their bearings in particular must also be able to withstand high static loads over the long term.

Suitable storage material:

iglidur GInterior and engine compartment

Steering linkage

Steering systems must primarily operate lubrication-free, clearance-free and noise-free. The choice of bearing is therefore particularly important here. In addition, there are impact loads when driving, which in the worst case can lead to increased wear of the bearing.

Suitable storage material:

iglidur J

Gear lever

When it comes to gear shifting, the main requirements are smooth, fluid movement and the quietest possible adjustment of the gear lever. At the same time, the focus is on economic efficiency, e.g. built-in bearings must function reliably with the lowest possible maintenance effort.

Suitable storage material:

iglidur J

Transmission

In transmissions, coupling rods must have a vibration-damping specification and high strength due to the vibrations. In addition, high media resistance is required here, as oil and grease can occur more frequently.

Suitable product:

igubal coupling joints

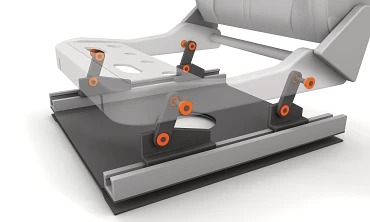

Seat adjustments

Plain bearings are often used in sheet metal for seat adjustments. Products that are easy to install and do not require time-consuming recalibration are particularly in demand here. Our clip bearings can do just that: they simply calibrate themselves through the effect of heat during the e-coating process.

Suitable bearing:

Clip bearing iglidur® M250